HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

NUZHUO Full Automatic Industrial Liquid Nitrogen Oxygen Production Plant Cryogenic Air Separation Unit

|

Product Name |

Cryogenic air separation equipment |

|

Model No. |

NZDON- 50/80/120/150/180/200/CUSTOMIZED |

|

Brand |

NuZhuo |

|

Accessories |

Air compressor & Re- cooling system & Expander & Cold box |

|

Usage |

High purity Oxygen & Nitrogen & Argon production machine |

|

Model |

NZDON-50/50 |

NZDON-80/160 |

NZDON-180/300 |

NZDON-260/500 |

NZDON-350/700 |

NZDON-550/1000 |

NZDON-750/1500 |

NZDON-1200/2000/0y |

|

O2 0utput (Nm3/h) |

50 |

80 |

180 |

260 |

350 |

550 |

750 |

1200 |

|

O2 Purity (%O2) |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

|

N2 0utput (Nm3/h) |

50 |

160 |

300 |

500 |

700 |

1000 |

1500 |

2000 |

|

N2 Purity (PPm O2) |

9.5 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

|

Liquid Argon Ouput ( Nm3/h) |

—— |

—— |

—— |

—— |

—— |

—— |

—— |

30 |

|

Liquid Argon Purity ( Ppm O2 + PPm N2) |

—— |

—— |

—— |

—— |

—— |

—— |

—— |

≤1.5ppmO2 + 4 p p mN2 |

|

Liquid Argon Purity ( Ppm O2 + PPm N2) |

—— |

—— |

—— |

—— |

—— |

—— |

—— |

0.2 |

|

Consumption (Kwh/Nm3 O2) |

≤1.3 |

≤0.85 |

≤0.68 |

≤0.68 |

≤0.65 |

≤0.65 |

≤0.63 |

≤0.55 |

|

Occupied Area (m3) |

145 |

150 |

160 |

180 |

250 |

420 |

450 |

800 |

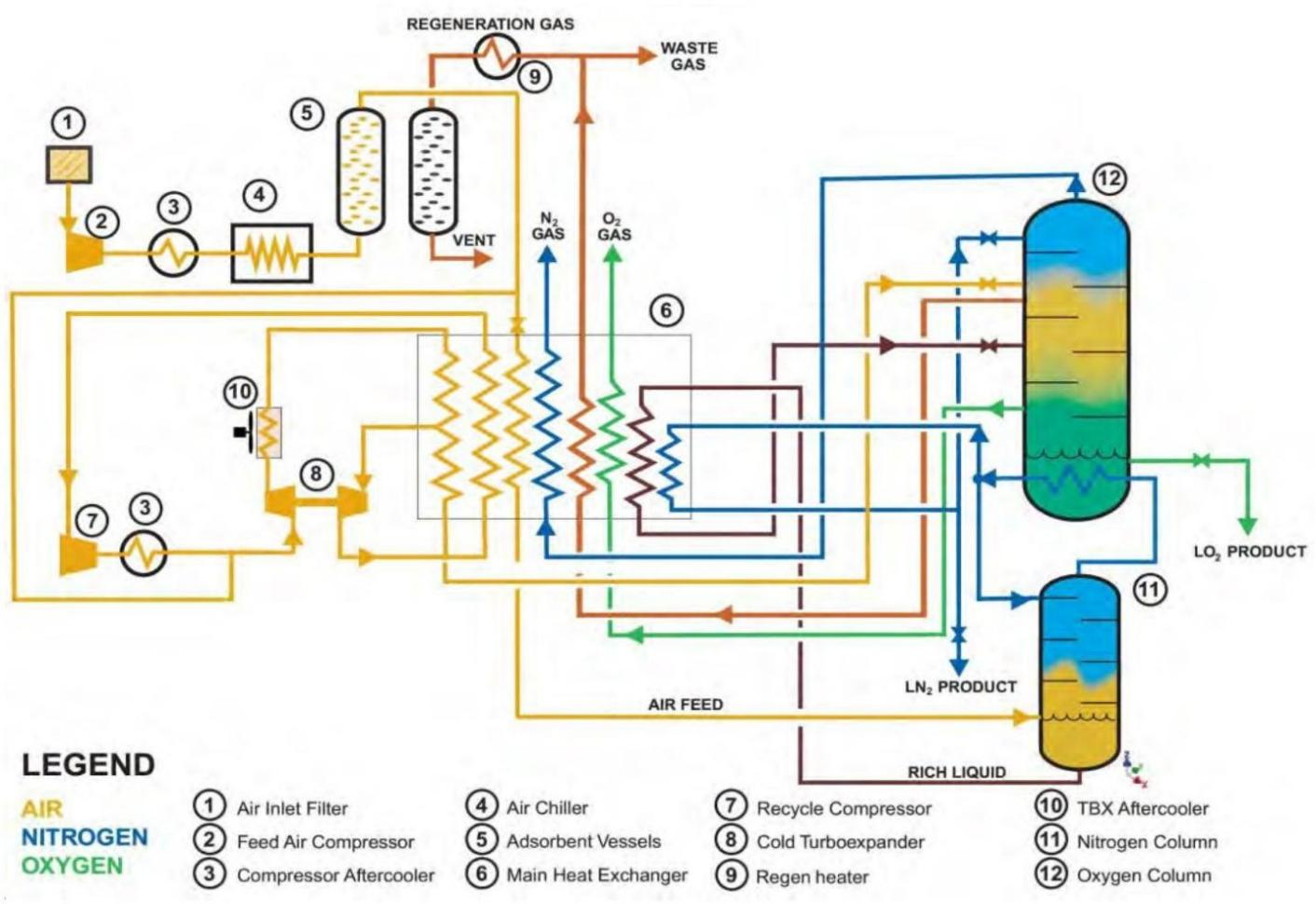

The basic principle of air separation is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen-enriched liquid air. The oxygen-enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid-air inlet as the boundary, the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove the nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

1、Air Compressor: Air be compressed to 0.5-0.7Mpa by air compressor

2、Pre-cooling: The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated.

3、Air purification system:Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier;

4、Air expansion:The air expands and cools in the turbo expander and provides the cooling capacity required by the device

5、Heat Exchange:The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature;

6、Cooling:Cooling the liquid air and liquid nitrogen before the throttling of the nitrogen in the chiller.

7、Distillation:The air is rectified and separated in the rectification tower, and the product nitrogen is obtained at the top of the upper tower, and the product oxygen is obtained at the bottom of the upper tower.

1.Air Separation Unit with normal temperature molecular sieves purification, booster-turbo expander, low-pressure rectification column, and argon extraction system according to client’s requirement.

2.According to the product requirement, external compression,internal compression (air boost,nitrogen boost),self- pressurization and other processes can be offered.

3.Blocking structure design of ASU, quick installation on site.

4.Extra low pressure process of ASU which reduce air compressor exhaust pressure and operation cost.

5.Advanced argon extraction process and higher argon extraction rate.

IF YOU HAVE ANY INTERSTS TO KNOW MORE INFORMATION, CONTACT US: 0086-18069835230

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.