-

2022 China New Design High Quality and Efficient Oxygen Generator Air Separation Plant Unit

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Industrial Liquid Oxygene Production Plant NZDO-50 Cryogenic Air Separation Oxygen

Cryogenic air separation units play a significant role in a wide array of industrial settings, providing a high rate of pure oxygen, nitrogen, and argon, liquid or gaseous product, for many critical applications.

-

Factory Supply Cryogenic Distillation Air Separation Plant Liquid Oxygen Nitrogen Argon Production Plant

1.Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2.Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3.Purification of Air By Purifier: Twin molecular Sieve driers

4.Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5.Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6.Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank -

OEM/ODM Supplier Cryogenic Liquid Air Separation Unit Liquid Oxygen Nitrogen Generator Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

Cheap price 50-1000nm3/H Liquid Oxygen Nitrogen Cryogenic Air Separation Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

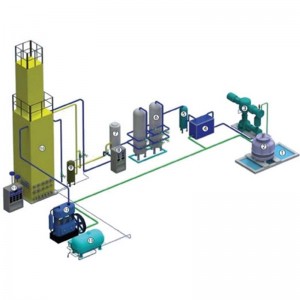

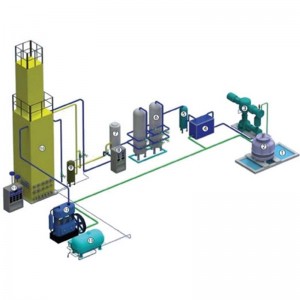

Popular Design for OEM Manufacturer Supplier Psa Oxygen Generator with Cylinder Filling System

Adsorbent: Zeolite Molecular Sieve

Application: Industrial & Medical use

Technology: Pressure swing adsorption

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Booster, Air dryer, Filter, storage tank, etc

Advantage: Rectification column, Desorption, Regeneration, Alternating cycle,etc -

Popular Design for OEM Manufacturer Supplier Psa Oxygen Generator with Cylinder Filling System

Adsorbent: Zeolite Molecular Sieve

Application: Industrial & Medical use

Technology: Pressure swing adsorption

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Booster, Air dryer, Filter, storage tank, etc

Advantage: Rectification column, Desorption, Regeneration, Alternating cycle,etc -

Popular Design for OEM Manufacturer Supplier Psa Oxygen Generator with Cylinder Filling System

Adsorbent: Zeolite Molecular Sieve

Application: Industrial & Medical use

Technology: Pressure swing adsorption

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Booster, Air dryer, Filter, storage tank, etc

Advantage: Rectification column, Desorption, Regeneration, Alternating cycle,etc -

Popular Design for OEM Manufacturer Supplier Psa Oxygen Generator with Cylinder Filling System

Adsorbent: Zeolite Molecular Sieve

Application: Industrial & Medical use

Technology: Pressure swing adsorption

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Booster, Air dryer, Filter, storage tank, etc

Advantage: Rectification column, Desorption, Regeneration, Alternating cycle,etc -

Popular Design for OEM Manufacturer Supplier Psa Oxygen Generator with Cylinder Filling System

Adsorbent: Zeolite Molecular Sieve

Application: Industrial & Medical use

Technology: Pressure swing adsorption

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Booster, Air dryer, Filter, storage tank, etc

Advantage: Rectification column, Desorption, Regeneration, Alternating cycle,etc -

Special Design for Wholesale Oxygen Plant Psa Oxygen Generator

Adsorbent: Zeolite Molecular Sieve

Application: Industrial & Medical use

Technology: Pressure swing adsorption

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Booster, Air dryer, Filter, storage tank, etc

Advantage: Rectification column, Desorption, Regeneration, Alternating cycle,etc -

Super Purchasing for Generator Oxygen Nitrogen on Generator of Liquid Nitrogen Generator Nitrogen Laser Cutting

Purity : 95%-99.999%

Application: Industrial use & Medical Use & Laboratory

Technology: Pressure swing adsorption & Frozen liquefaction

Easy Operating: PLC intelligent control system

Accessory Equipment: Air compressor, Air dryer, PSA Nitrogen Generator, Liquid Nitrogen Generator

Advantage: Small liquid nitrogen production machine, 5LPD-50LPH

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com