HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

NUZHUO Nitrogen Generator 60Nm3 Nitrogen Making Machine For Food Preservation

Our medium size oxygen/nitrogen plants are designed and manufactured with the latest cryogenic air separation technology, which is trusted as the most efficient technology for high rate of gas generation with high purity. We have world-class engineering expertise enabling us to build industrial gas systems in compliance with internationally approved manufacturing and designing standards. Our plant machinery is fabricated after taking into various variables including number of gaseous and liquid products to be produced, purity specifications, local environmental conditions and desired pressure delivery

|

Specification |

Output (Nm3/h) |

Effective gas consumption ( Nm3/h ) |

Air cleaning system |

Inlet/outlet caliber(mm) |

|

|

XSN59-5 |

5 |

0.78 |

KJ-1 |

DN25 |

DN15 |

|

XSN59-10 |

10 |

1.75 |

KJ-2 |

DN25 |

DN15 |

|

XSN59-20 |

20 |

3.55 |

KJ-6 |

DN40 |

DN15 |

|

XSN59-30 |

30 |

5.25 |

KJ-6 |

DN40 |

DN25 |

|

XSN59-40 |

40 |

7.0 |

KJ-10 |

DN50 |

DN25 |

|

XSN59-50 |

50 |

8.7 |

KJ-10 |

DN50 |

DN25 |

|

XSN59-60 |

60 |

10.5 |

KJ-12 |

DN50 |

DN32 |

|

XSN59-80 |

80 |

13.75 |

KJ-20 |

DN65 |

DN40 |

|

XSN59-100 |

100 |

16.64 |

KJ-20 |

DN65 |

DN40 |

|

XSN59-150 |

150 |

24.91 |

KJ-30 |

DN80 |

DN40 |

|

XSN59-200 |

200 |

33.37 |

KJ-40 |

DN100 |

DN50 |

|

XSN59-300 |

300 |

49.82 |

KJ-60 |

DN125 |

DN50 |

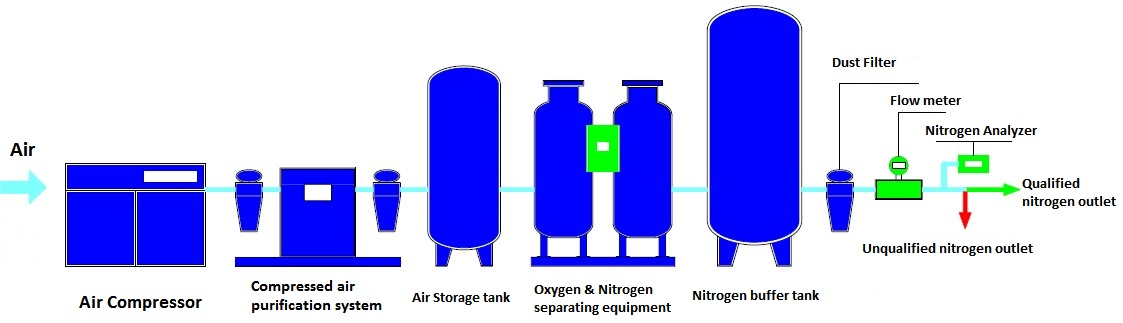

Pressure swing adsorption (PSA) process is made up two vessels filled with molecular sieves and activated alumina. Compressed air is passed through one vessel at 30 degrees C and oxygen is generated as a product gas. Nitrogen is discharged as an exhaust gas back into atmosphere. When the molecular sieve bed is saturated, the process is switched to the other bed by automatic valves foroxygen generation.

It is done while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Two vessels keep working alternately in oxygen production and regeneration allowing oxygen is available to the process.

1. PSA Nitrogen Plant adopts the principle that under a certain pressure, the diffusion speeds of oxygen and nitrogen are quite different on carbon molecular sieve. In a short time, oxygen molecule is adsorbed by the carbon molecular sieve but nitrogen can pass through the molecular sieve bed layer to separate the oxygen and nitrogen.

2. After the adsorption process, the carbon molecular sieve will regenerate by depressurizing and desorb the oxygen.

3. Our PSA Nitrogen Plant is equiped with 2 adsorbers, one in adsorption to produce nitrogen, one in desorption to regenerate the molecular sieve. Two adsorbers work alternately to generate qualified product nitrogen continuously.

PSA nitrogen generator, PSA Oxygen purifier, PSA nitrogen purifier, hydrogen generator, VPSA oxygen generator,Membrane oxygen generator, Membrane nitrogen generator, Liquid (cryogenic) oxygen, nitrogen and argon generator, etc,and are widely used in industries of petroleum, oil & gas, chemicals, electronics, metallurgy, coals, pharmaceuticals, aerospace, autos, glass, plastics, food, medical treatment, grain, mining, cutting, welding, new material, etc. With years research in air separation technology and rich solution experiences in various industries, sticks to providing our clients with more reliable, more economical, more convenient professional gas solutions.

If you have any intersts to know more information, contact us: 0086-18069835230

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.