The air separation tower is an important piece of equipment used to separate the main gas components in the air into nitrogen, oxygen, and other rare gases. Its process flow mainly involves steps such as air compression, pre-cooling, purification, cooling, and distillation. Each step’s precise control is crucial for ensuring the purity and stability of the final gas products. This article will provide a detailed introduction to the process flow of the air separation tower.

1. Air Compression and Pre-cooling

The first step in the air separation tower process is to compress the atmospheric air. Through multiple stages of air compressors, the air is compressed to a pressure of 5-7 bar. During the compression process, the temperature of the compressed air also rises, so intermediate coolers and post-coolers are used to lower the temperature of the air. To prevent the compressor from being damaged by impurities in the air, particles in the air are removed through filters. The compressed air is then sent to the pre-cooling system for further cooling, typically using cooling water or refrigerants such as Freon, to cool the air to approximately 5°C.

2. Air Purification and Dehydration

After pre-cooling, the air contains a small amount of moisture and carbon dioxide. These impurities may form ice at low temperatures and block equipment. Therefore, the air needs to be purified and dehydrated. This process typically uses molecular sieve adsorption towers, through periodic adsorption and regeneration processes to remove water vapor, carbon dioxide, and hydrocarbons, etc., to ensure the smooth operation of the subsequent low-temperature processes. The purified air is clean and dry, suitable for subsequent cooling and separation processes.

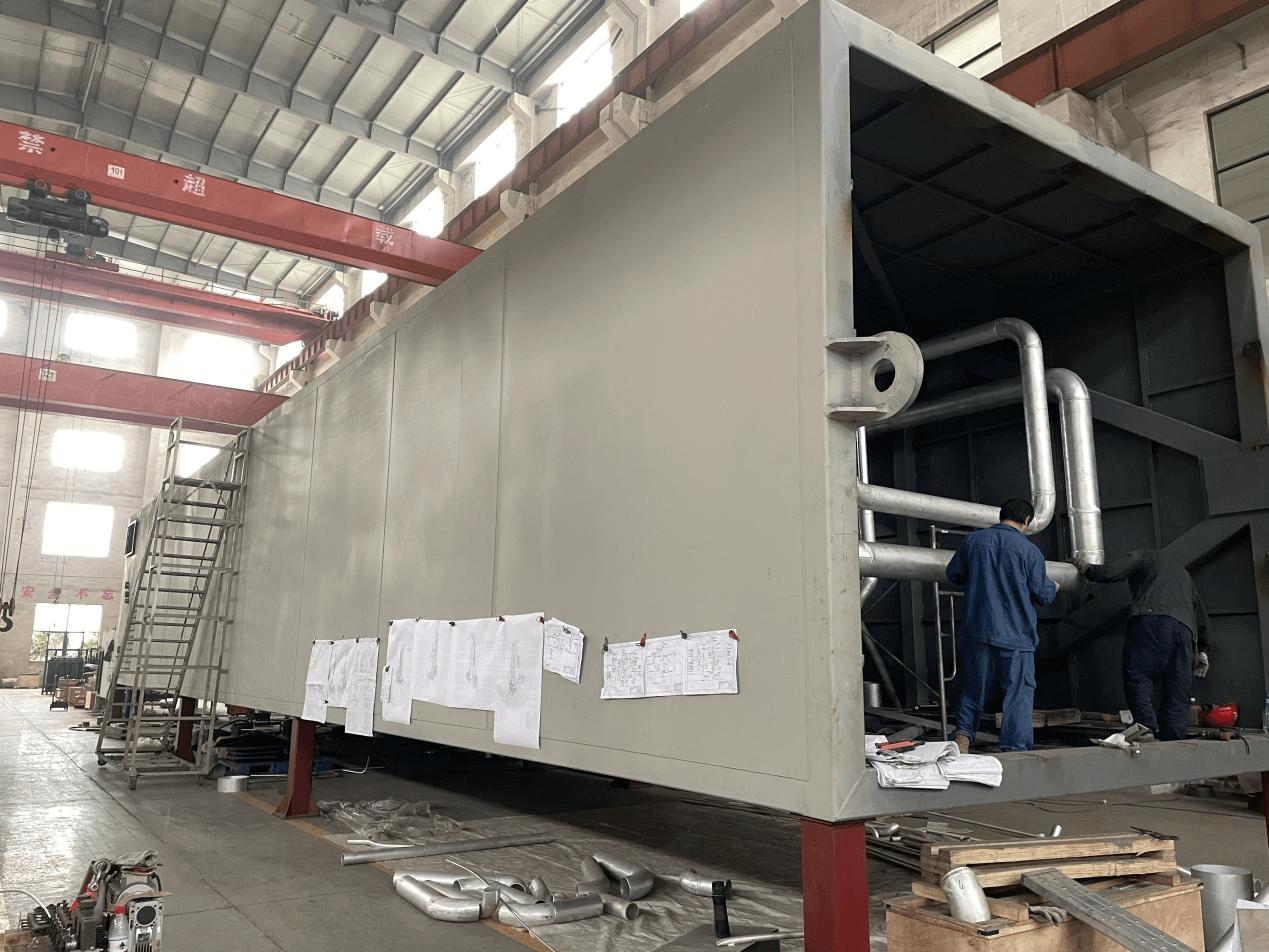

3. Main Heat Exchanger Cooling the Air

The purified air is cooled in the main heat exchanger through deep cooling. The main heat exchanger is one of the most critical equipment in the air separation tower process. The air in the main heat exchanger undergoes heat exchange with the separated cold nitrogen and oxygen, lowering its temperature to close to the liquefaction temperature. The heat exchange efficiency during this process directly affects the energy consumption and purity of the final product of the air separation tower. Typically, efficient aluminum plate fin heat exchangers are used to improve heat exchange efficiency.

4. Separation Process in the Distillation Tower

The cooled air is sent to the distillation tower for separation using the difference in boiling points of the various components in the air. The air gradually liquefies at low temperatures, forming liquid air. This liquid air enters the distillation tower for multiple interactions between gas and liquid phases. In the distillation tower, oxygen, nitrogen, and rare gases such as argon are separated. The oxygen concentration gradually increases at the bottom of the tower, while nitrogen is separated at the top. Through distillation, pure oxygen and nitrogen can be obtained with higher purity.

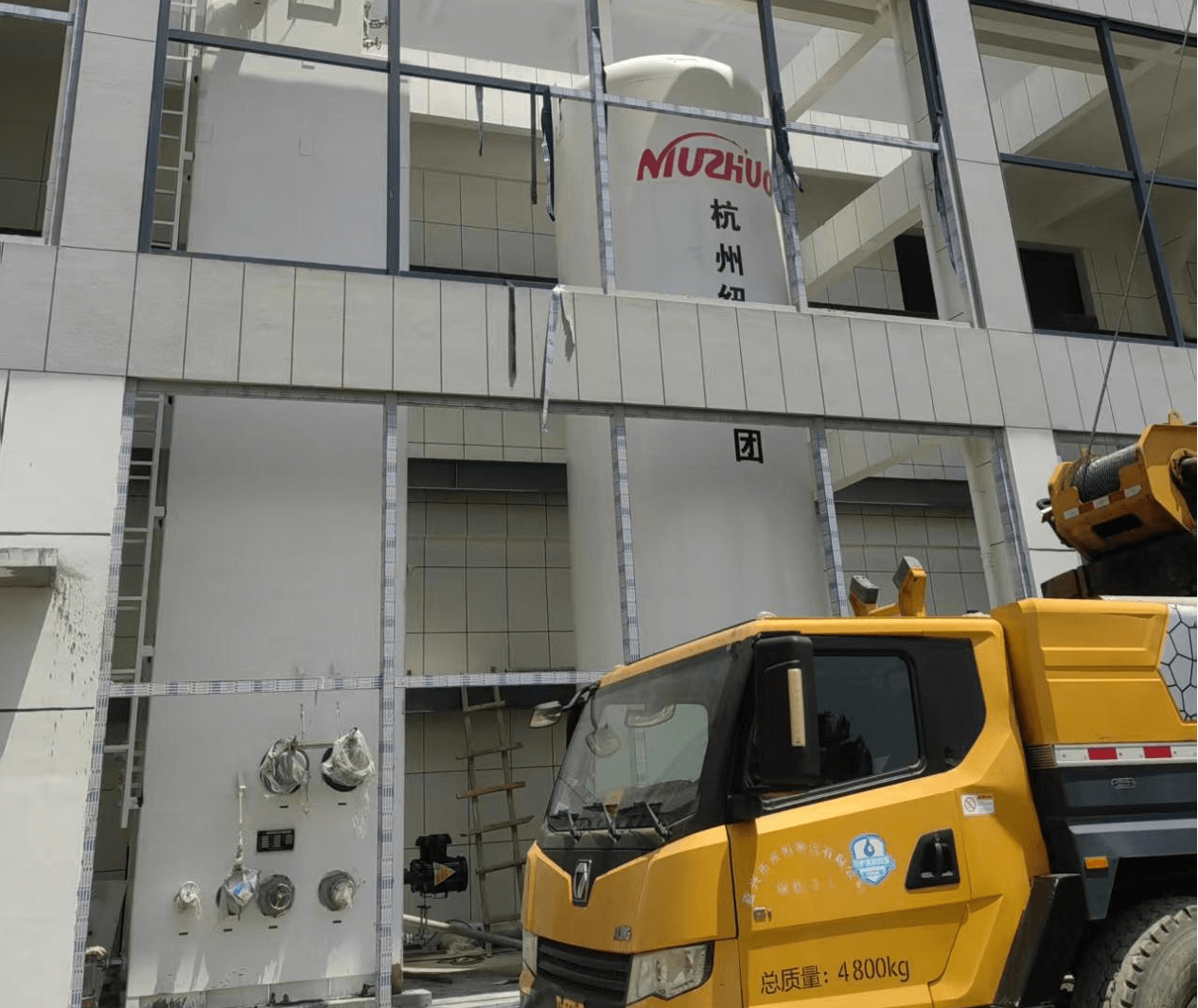

5. Extraction of Oxygen and Nitrogen Products

The extraction of oxygen and nitrogen is the final step of the air separation tower. Liquid oxygen and nitrogen are separated from the distillation tower and heated back to room temperature through heat exchangers to reach the desired gaseous state. These gas products are further sent to storage tanks or directly supplied to users. To improve process efficiency and product purity, a double-tower structure is sometimes designed to further separate argon from oxygen and nitrogen for industrial use.

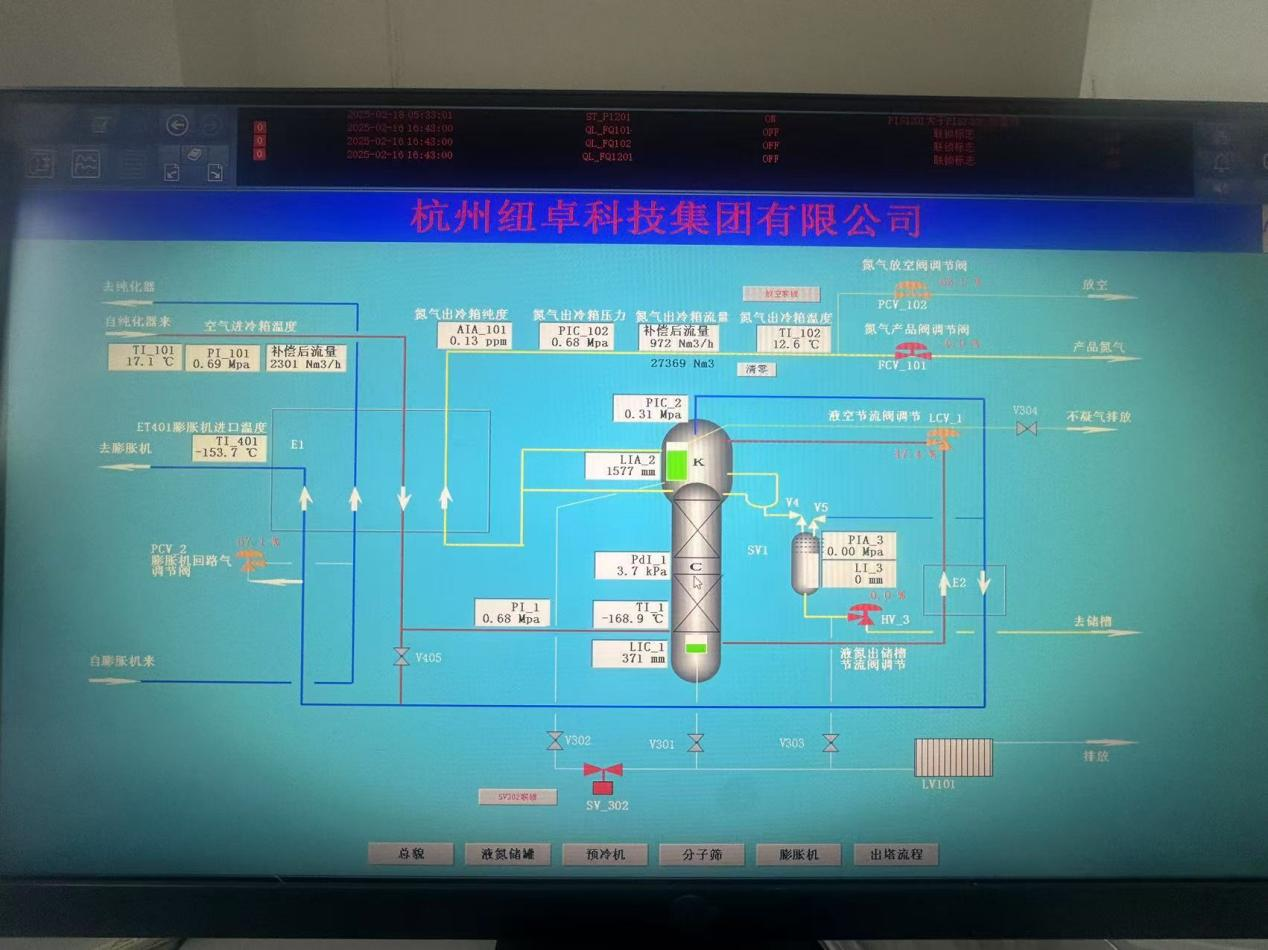

6. Control and Optimization

The entire air separation tower process involves a complex control system, requiring real-time monitoring and adjustment of the compression, cooling, heat exchange, and separation processes to ensure the quality of the final products. Modern air separation towers are typically equipped with automated control systems, using sensors and control software to precisely regulate parameters such as temperature, pressure, and flow to optimize production process energy consumption and gas product purity.

The process flow of the air separation tower includes multiple steps such as air compression, pre-cooling, purification, deep cooling, and distillation. Through these processes, oxygen, nitrogen, and rare gases in the air can be effectively separated. The development of modern air separation tower technology has made the separation process more efficient and low-energy consumption, which is of great significance for the application of industrial gases.

For any oxygen/nitrogen needs, please reach out to us :

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Post time: Jul-07-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com