HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

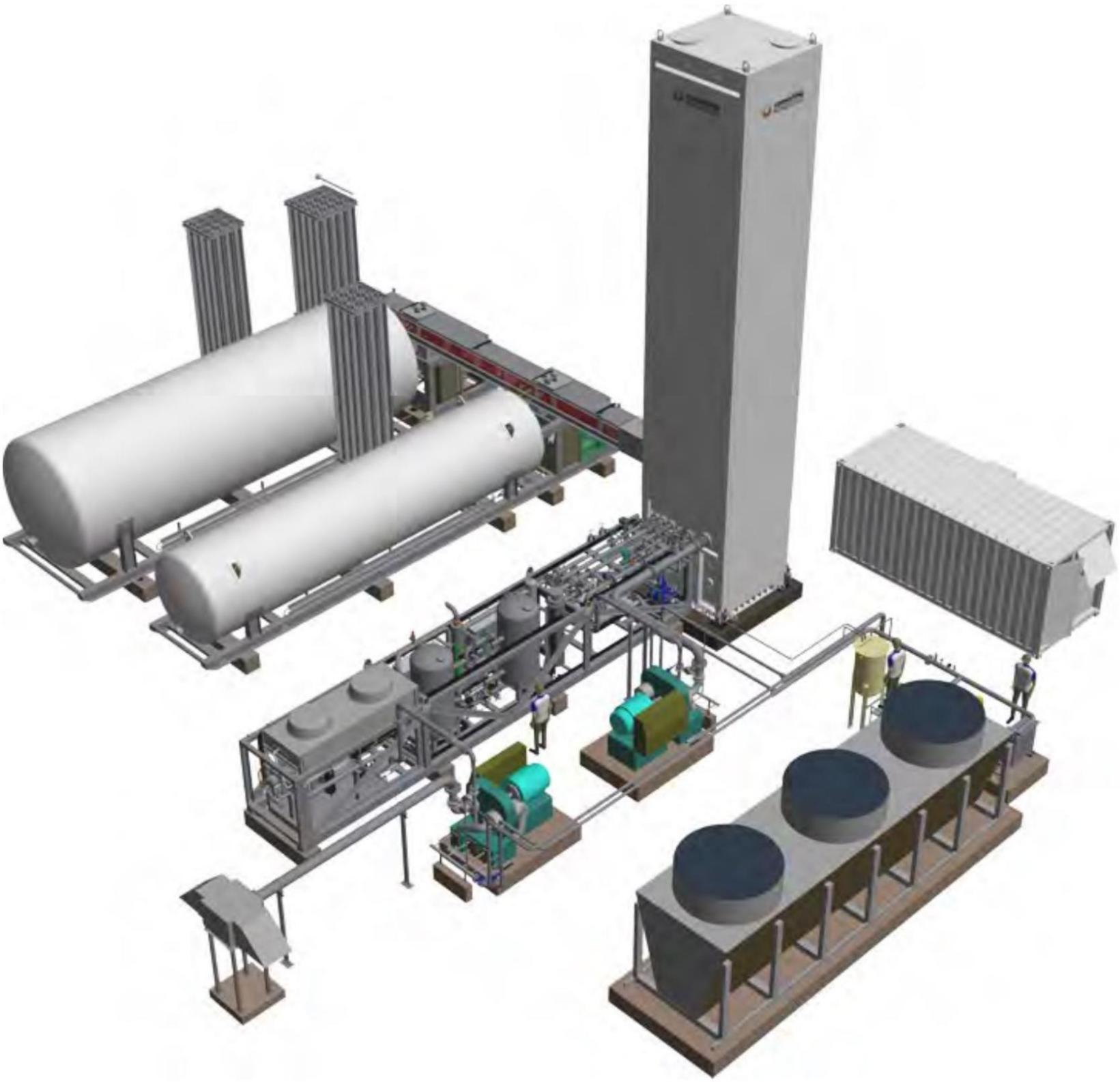

NUZHUO High Purity Oxygen Plant Manufacturer Cryogenic Air Separation Liquid Oxygen Plant

Specifications of the Nuzhuo Air separation unit :

| No | MAIN PART | FUNCTION |

| 1 | Air Compression System | Air be compressed to 0.5-0.7 Mpa by air compressor, Imported centrifugal air compressor, high efficiency, low consumption,stable and reliable operation |

|

2 |

Pre-cooling System |

The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated. The original importedscrew refrigeration compressor and the air-conditioning unit combined with all imported refrigeration

components are equipped with a water separator, manual and imported automatic drains to drain water regularly. |

|

3 |

Air Purification System |

Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecularsieve purifier. The purifier adopts a vertical single-layer bed with simple and reliable structure and low

resistance loss; built-in filter, blowing off and purifier regeneration at the same time; high-efficiency electric heater ensures complete regeneration of molecular sieve |

|

4 |

Fractionating Column System (Cold Box) |

The heating, cooling, liquid accumulation and purification of the fractionating tower can be completed in oneway, and the operation is simple, quick and easy. Adopt aluminum plate-fin heat exchanger, aluminum

convection sieve plate tower, the entire fractionating tower equipment pipeline adopts argon arc welding, the tower body and main pipeline in the cold box are made of high-strength aluminum alloy or stainless steel to increase the strength , Reduce the torsion damage of the pipeline. The equipment brackets, pipes and valve brackets in the cold box shall be made of stainless steel or aluminum alloy. The cold box is insulated with pearl sand and slag wool to ensure that the loss of cold capacity is minimized. The cold box structure guarantees the overall strength and the requirements of anti-seismic and wind resistance, and guarantees the load-bearing capacity of the cold box. When the cold box is running, it is equipped with airtight protection and safety devices. The main equipment in the cold box is equipped with electrostatic grounding. The cold valve and pipeline in the cold box all connections are welded, and flange connections are avoided. |

| 5 | Turbo Expander System | The air expands and cools in the turbo expander and provides the cooling capacity required by the device.Theturbo expander adopts gas bearing, which is simple and reliable, easy to operate, and high efficiency. The cold

box of the expander is set separately for easy maintenance. |

| 6 | Heat Exchange System | The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger ofthe fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen,

and dirty nitrogen are repeatedly heat exchanged to the ambient temperature; |

| 6 | Filling System | Single gas production: Internal compression process ( Cryogenic liquid pump, High pressure vaporizer, Filling manifold).Multi-gas production: External compression process (Oxygen & nitrogen & argon booster, Filling manifold). |

| 7 | Instrument and Electric Control System | Siemens imported brand, Fully automatic production system, Digital control system |

| 8 | Others | Equipment layout drawing (according to civil engineering design), Process pipe design drawings,Instrument electrical design drawings, etc. |

FAQ:

Q1: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q2: What is your term of payment?

A: T/T 30% in advance and T/T 70% balance paid before shipment.

Q3 How long is your delivery time?

A: About 30 days.

Q4: What is your product quality assurance policy?

A: We offer a warranty period of 1 year or 1000 running hours whichever comes first.

Q5: Do you offer OEM/ODM service?

A: Yes.

Q6: Do you have ATS system?

A: Yes, it is optional.

About Hanghzou Nuzhuo Group :

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.