Liquid oxygen is a pale blue liquid at low temperatures, with high density and extremely low temperature. The boiling point of liquid oxygen is -183℃, which makes it stable in low-temperature environments compared to gaseous oxygen. In liquid form, the density of oxygen is approximately 1.14 g/cm³, making liquid oxygen easier to store and transport than gaseous oxygen. Liquid oxygen not only has a high oxygen concentration but also has strong oxidizing properties, capable of rapidly reacting with many organic substances.

The low-temperature characteristic of liquid oxygen requires special equipment and measures during storage and transportation, such as using low-temperature insulated containers to prevent heat transfer. It is odorless and colorless, but due to its extremely low temperature, liquid oxygen may cause frostbite and other hazards to the human body, so special care is needed during operation.

The production and manufacturing process of liquid oxygen

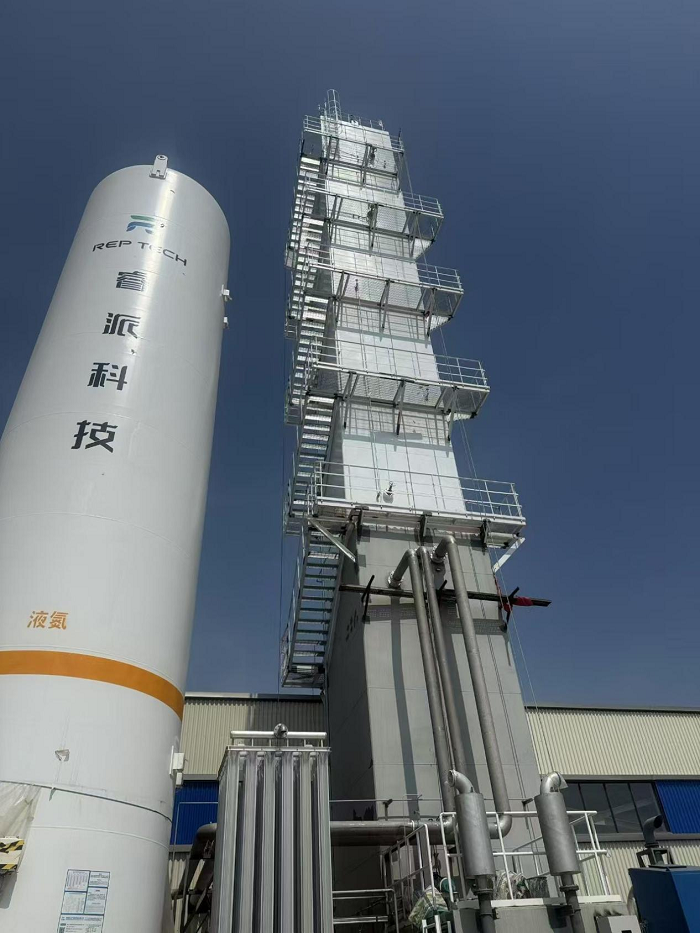

The production of liquid oxygen usually adopts deep cryogenic air separation technology, which is a method of separating the components of air through low-temperature cooling and efficient compression. The basic principle of deep cryogenic air separation is to separate the various components of air based on their different boiling points. First, the air is compressed, then through multiple stages of expansion and cooling, the air gradually reaches an extremely low temperature, and finally oxygen is separated from the air and liquefied. The production of liquid oxygen requires efficient cooling systems and purification devices to ensure the purity and stability of liquid oxygen.

Deep cryogenic air separation technology can not only produce liquid oxygen but also simultaneously obtain other low-temperature gases such as liquid nitrogen and liquid argon. These products also have wide applications in industry. The high purity and low-temperature characteristics of liquid oxygen make it important in many special industrial applications.

The main application fields of liquid oxygen

Liquid oxygen has extensive applications in many industrial fields. Firstly, in the aerospace field, liquid oxygen is one of the commonly used rocket oxidants, as it has a high oxygen content and combustion assistance ability, which can react with fuel rapidly to generate a large amount of energy to propel rocket launches. The combination of liquid oxygen and liquid hydrogen is called one of the most common rocket propellants, and its powerful thrust and excellent performance make it highly favored in aerospace technology.

Secondly, in the medical field, liquid oxygen is used as an important oxygen source. Liquid oxygen is stored at low temperatures and vaporized for use as medical oxygen, helping patients with breathing difficulties obtain sufficient oxygen supply. In addition, liquid oxygen plays an important role in metallurgy, chemical engineering, and other fields, especially in high-temperature combustion and chemical synthesis processes, where its strong oxidizing ability is widely utilized.

Safety precautions for liquid oxygen

Although liquid oxygen has wide applications, due to its high reactivity and low-temperature characteristics, there are certain safety hazards. Firstly, liquid oxygen is a strong oxidant, which can accelerate the combustion process, so it must be avoided from contact with flammable substances during storage and use. At the same time, the extremely low temperature of liquid oxygen may cause frostbite, so appropriate protective equipment such as cold-resistant gloves and masks must be worn during liquid oxygen operation to avoid skin and eye injuries.

The storage of liquid oxygen requires special designed low-temperature containers, which usually have good insulation properties to prevent external heat from entering and causing the temperature of liquid oxygen to rise. In addition, during the vaporization process of liquid oxygen, it will rapidly expand and produce a large amount of oxygen, which may lead to an increase in oxygen concentration in the environment, increasing the risk of fire. Therefore, during the storage and transportation of liquid oxygen, relevant safety regulations must be strictly followed to ensure a safe working environment and ventilation.

Comparison of liquid oxygen with other industrial gases

Liquid oxygen, like liquid nitrogen and liquid argon, shares some similar physical properties, but there are significant differences in application and properties. The boiling point of liquid nitrogen is -196℃, which is lower than that of liquid oxygen, so liquid nitrogen is often used as a coolant, while liquid oxygen, due to its strong oxidizing properties, is often used as a combustion aid or oxidant. Furthermore, liquid argon, as an inert gas, is not prone to react with other substances during chemical reactions and is mainly used for protecting the atmosphere. While liquid oxygen, due to its high reactivity, is commonly used in chemical synthesis and combustion processes.

Among these industrial gases, liquid oxygen is distinctive due to its strong oxidizing property, especially in scenarios requiring efficient combustion and intense oxidation reactions. The characteristics of different industrial gases enable them to play significant roles in their respective application fields.

The environmental friendliness and sustainability of liquid oxygen

Although liquid oxygen, as an industrial gas, has a relatively high reactivity in application, it does not cause pollution to the environment in essence. Oxygen, as an important component of the atmosphere, its final products in the reaction process are mostly harmless substances such as water or carbon dioxide. However, the production process of liquid oxygen requires a large amount of energy, especially in the deep cooling separation process, so improving the energy efficiency of liquid oxygen production is of great significance for environmental protection.

By using more efficient equipment and improving process flows, it is possible to reduce energy consumption while minimizing the environmental impact of liquid oxygen production. With the development of green energy technologies, the production of liquid oxygen is expected to become more environmentally friendly and sustainable in the future, providing a cleaner source of oxygen for industrial production and human life. Conclusion

Liquid oxygen, as a liquid form of oxygen, has been widely used in industries, aerospace, and healthcare due to its unique physical properties and strong oxidizing nature. Although the production and use of liquid oxygen require strict safety measures, its significant role in many fields is irreplaceable. In the future, with the continuous advancement of technology, the production and application of liquid oxygen are expected to become more efficient and environmentally friendly, thus better meeting the needs of society.

We are manufacturer and exporter of air separation unit. If you want to know more about us:

Contact person:Anna

Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Post time: Sep-08-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com