The cryogenic nitrogen production equipment plays a crucial role in the industrial sector, being widely used in fields such as chemical engineering, metallurgy, and electronics. The performance of the equipment is closely related to the operating environment, especially the altitude, which has a significant impact on its efficiency and stability. This article will explore the specific effects of altitude on cryogenic nitrogen production equipment and how to optimize its performance in different altitude environments.

1. The impact of altitude on air density

The increase in altitude leads to a decrease in air density, which directly affects the efficiency of cryogenic nitrogen production equipment. In lower-altitude areas, the air density is higher, allowing the equipment to more effectively inhale and compress air, thereby increasing the output and purity of nitrogen. However, as the altitude rises, the air becomes thinner, and the equipment may not be able to obtain sufficient air volume during the inhalation stage, thereby affecting the production rate of nitrogen. This change requires manufacturers to consider altitude factors when designing the equipment to ensure its efficient operation at different heights.

2. The influence of temperature on equipment performance

Altitude is usually accompanied by a decrease in temperature. In some cases, lower temperatures can help improve cooling efficiency, but they may also cause equipment operation instability. Cryogenic nitrogen production equipment needs to work within a specific temperature range to ensure the effectiveness of the nitrogen production process. Low temperatures may cause the fluidity of the refrigerant to decrease, affecting the cooling effect. Therefore, in high-altitude regions, users need to regularly check the temperature control system of the equipment to prevent failures caused by temperature changes.

3. Equipment selection and configuration

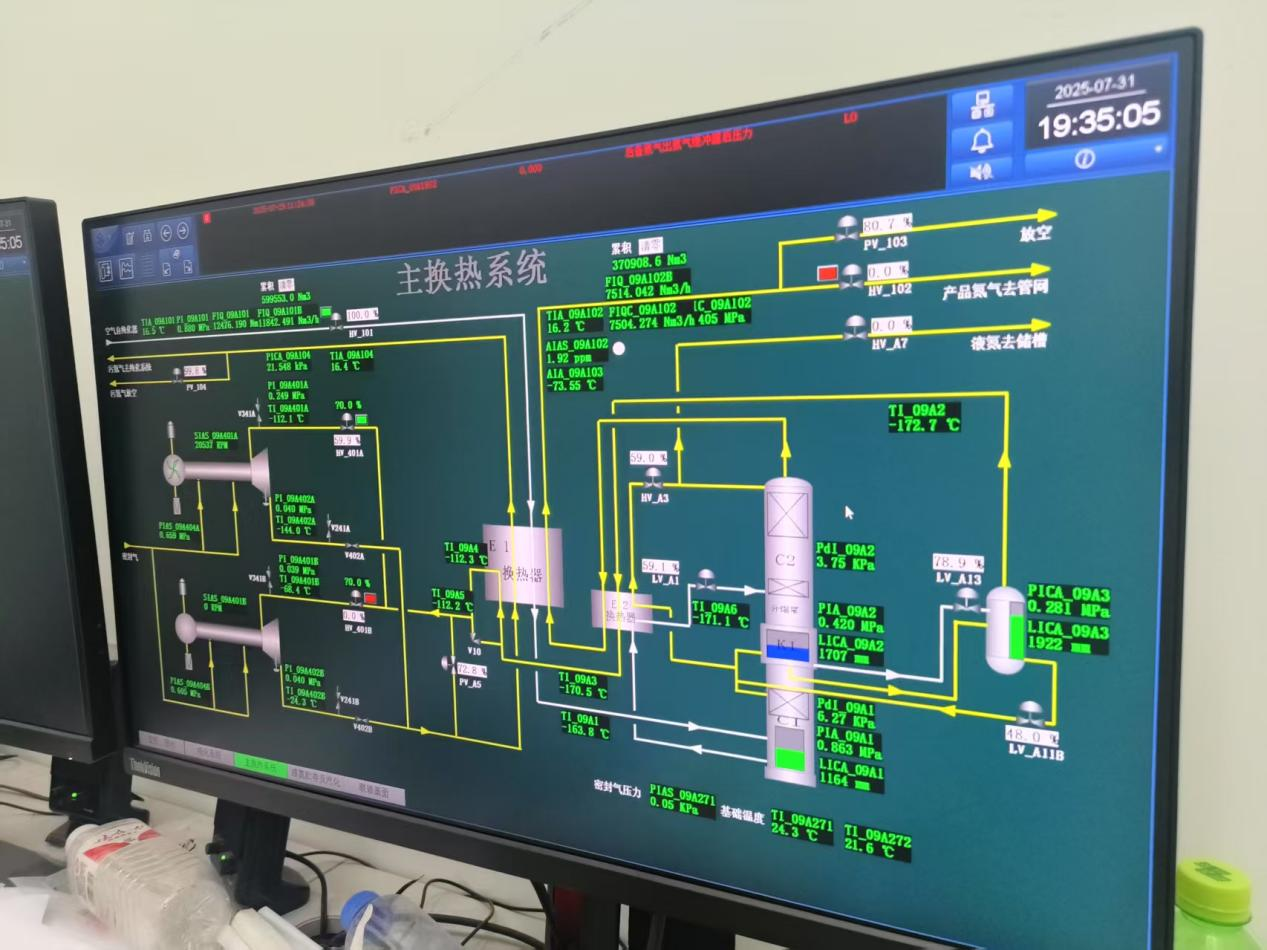

For different altitude environments, the selection and configuration of cryogenic nitrogen production equipment are particularly important. In high-altitude areas, it is recommended to choose equipment with efficient compression and cooling capabilities, and to equip it with advanced control systems to monitor and adjust the equipment’s operating status in real time. Additionally, a booster device can be considered to improve the equipment’s suction capacity in thin air environments. This configuration not only enhances the nitrogen production efficiency but also helps extend the equipment’s service life.

4. System maintenance and management

The climate conditions in high-altitude regions pose higher requirements for equipment maintenance and management. Due to changes in temperature and humidity, the lubrication and sealing systems of the equipment may be affected. Regular maintenance and inspections are crucial for maintaining the equipment’s optimal performance. It is recommended that users establish detailed maintenance records and regularly inspect key components of the equipment, including compressors, condensers, and evaporators, to ensure their normal operation.

5. Economic analysis and cost assessment

Operating cryogenic nitrogen production equipment in high-altitude regions may increase operational costs, including equipment investment, energy consumption, and maintenance expenses. Therefore, when selecting equipment and making project investments, a comprehensive economic analysis must be conducted. Considering the specific needs of high-altitude regions, enterprises should allocate sufficient funds in the budget to address potential additional expenditures. At the same time, by optimizing production processes and improving energy efficiency, the overall operating costs can be reduced. Conclusion

The impact of altitude on deep cryogenic nitrogen production equipment is multifaceted, including factors such as air density, temperature, equipment selection and configuration, system maintenance, and economic efficiency. To ensure the stable operation of the equipment under different altitude conditions, enterprises should fully consider these influencing factors during design and operation. Through reasonable configuration and regular maintenance, deep cryogenic nitrogen production equipment can not only operate efficiently in high-altitude areas, but also contribute to the sustainable development of related industries.

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Post time: Aug-11-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com