Liquid nitrogen and liquid oxygen are two commonly used cryogenic liquids in industry and research. Each has its own wide-ranging and unique applications. Both are produced through air separation, but due to their different chemical and physical properties, they have distinct characteristics in practical applications. This article will explore the specific applications of liquid nitrogen and liquid oxygen and their differences.

I. Applications of Liquid Nitrogen

Liquid nitrogen is obtained by cooling air to below the boiling point of nitrogen. Its main component is nitrogen gas (N₂). The low-temperature property of liquid nitrogen makes it widely applicable, mainly including the following aspects:

Low-temperature freezing and preservation

One of the most common uses of liquid nitrogen is for low-temperature freezing and preservation, especially in the field of biomedicine. The temperature of liquid nitrogen is as low as −196°C, which can quickly freeze biological tissues, cells, and embryos and preserve them for a long time, ensuring their activity. These applications are of great significance in medical research, organ transplantation, and experimental animal breeding.

Food freezing

In the food processing field, liquid nitrogen is used for rapid freezing of food, such as seafood, meat, and fruits. Liquid nitrogen freezing can rapidly lower the temperature of food, thereby reducing the formation of ice crystals and protecting the taste and nutritional value of the food.

Cooling and refrigeration

Liquid nitrogen is also often used for the cooling and temperature control of mechanical equipment. For example, liquid nitrogen can be used as a cooling medium to reduce friction and heat in mechanical processing, thereby improving processing accuracy and efficiency.

Applications of gaseous nitrogen: Liquid nitrogen can also provide high-purity nitrogen gas after vaporization, which is widely used in the chemical industry as a protective gas to prevent oxidation reactions of harmful substances.

II. Applications of Liquid Oxygen

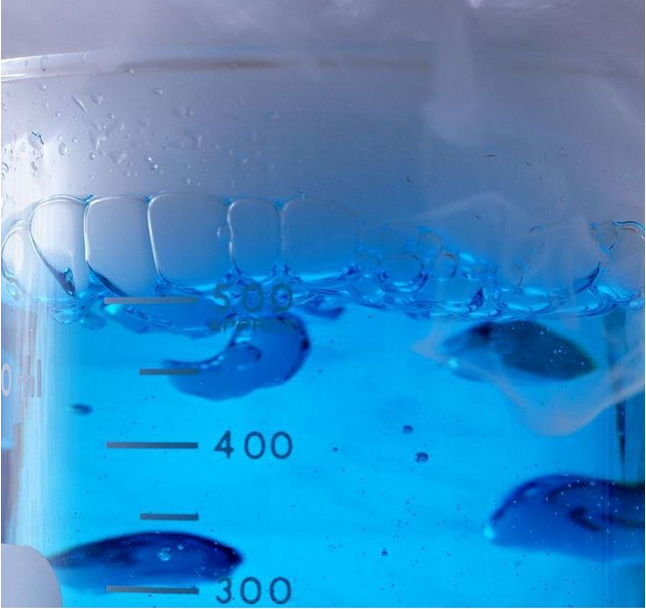

The main component of liquid oxygen is oxygen (O₂), which is also obtained through deep cryogenic separation technology. Oxygen, as an important element for life support and chemical reactions, has various applications, mainly reflected in the following aspects:

Medical oxygen supply

Liquid oxygen is widely used in hospitals and emergency care, providing high-concentration oxygen to patients to assist breathing. Especially in the treatment of respiratory diseases, oxygen supply is crucial. Liquid oxygen is small in volume, with a high oxygen content, convenient for storage and transportation, and is one of the preferred forms of medical oxygen supply.

Industrial oxidant

Liquid oxygen is commonly used as an oxidant in industry, especially in steel smelting and chemical production. Liquid oxygen can be used to assist combustion, increasing combustion temperature and reaction efficiency. For example, in the steel-making process, oxygen is injected into the molten iron water to remove impurities and improve the purity of steel.

Aerospace and rocket propulsion

Liquid oxygen is a commonly used auxiliary fuel in rocket propulsion systems, mixed with liquid fuel (such as liquid hydrogen) for combustion, generating extremely high energy to propel rockets into space. Its excellent auxiliary combustion properties make liquid oxygen an indispensable propellant in the aerospace industry.

III. Differences between Liquid Nitrogen and Liquid Oxygen

Although the applications of liquid nitrogen and liquid oxygen are distinctive, they have significant differences in nature and usage. Specifically:

1. Composition: Liquid nitrogen contains nitrogen gas (N₂), while liquid oxygen contains oxygen gas (O₂).

2. Density: Liquid nitrogen is denser than liquid oxygen.

3. Boiling point: Liquid nitrogen has a lower boiling point than liquid oxygen.

4. Usage: Liquid nitrogen is commonly used for freezing and preservation, while liquid oxygen is mainly used as an oxidant and a propellant. Chemical properties

Liquid nitrogen is essentially inert, with a very stable molecular structure that makes it unlikely to undergo chemical reactions with other substances. This property allows it to be used as a protective gas and applied in many chemical and industrial processes. On the other hand, liquid oxygen is a strong oxidizer with high chemical reactivity, and is prone to intense oxidation reactions with other substances, making it widely used in combustion and oxidation processes.

Temperature characteristics

The boiling point of liquid nitrogen is lower than that of liquid oxygen (liquid nitrogen -196°C, liquid oxygen -183°C), making it suitable for cooling and preservation at lower temperatures. Although liquid oxygen also belongs to a class of cryogenic liquids, its low-temperature performance is not as good as that of liquid nitrogen. Therefore, liquid oxygen is more commonly used for combustion and oxidation rather than cryogenic preservation. Safety

Liquid nitrogen is relatively safe to use because it is not prone to chemical reactions. The main risks are cold injury from the low temperature and the replacement of oxygen in the space, which may cause asphyxiation. While liquid oxygen, as an oxidizer, must be kept away from flammable substances such as oils to prevent combustion and explosion accidents. Therefore, it requires more caution during use.

Liquid nitrogen and liquid oxygen are two important low-temperature liquids. Although they are both produced through air separation, due to their different chemical and physical properties, their application fields have different focuses. Liquid nitrogen, with its inertness and low-temperature characteristics, is widely used in freezing preservation, food processing, and industrial cooling, etc. While liquid oxygen, relying on its oxidizing properties, is mainly used for medical oxygen supply, industrial oxidation, and aerospace propulsion, etc. In practical operations, the use of liquid nitrogen and liquid oxygen requires full consideration of their respective characteristics and safety to ensure their efficient application.

We are manufacturer and exporter of air separation unit. If you want to know more about us:

Contact person:Anna

Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Post time: Sep-22-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com