Nitrogen generators are essential for modern industrial production, underpinning processes from food preservation to electronics manufacturing. Extending their service life is not only key to cutting operational costs but also critical for avoiding unexpected production halts. This relies on systematic, consistent maintenance:

First, regularly replace filters and desiccants: Pre-filters (for coarse dust and oil mist) should be swapped every 3-6 months, while precision filters (trapping fine particles) and desiccants (absorbing moisture) need replacement every 6-12 months—adjust based on on-site air pollution (e.g., dusty workshops require more frequent changes). These components act as the system’s “first barrier”; neglecting replacement can let impurities enter the adsorption tower, clogging molecular sieves (reducing nitrogen purity by 5%-10% over time) or corroding the tower’s inner metal, shortening equipment life by years.

Second, monthly drainage and purity calibration: The water separator at the generator’s bottom accumulates condensed water daily—full drainage monthly prevents water from mixing with lubricating oil (which would reduce lubrication efficiency and cause bearing wear) and rusting metal pipelines. Use a professional nitrogen purity detector for monthly calibration; if purity falls below the required standard (e.g., 99.99% for electronics), adjust the adsorption cycle time or replace aging molecular sieves promptly to avoid long-term overload, which strains the air compressor.

Third, control ambient temperature and humidity: Maintain a working environment of 5°C-40°C and relative humidity ≤85%. Temperatures below 5°C thicken lubricating oil, increasing the air compressor’s load and energy consumption by 10%-15%; above 40°C, molecular sieve adsorption capacity drops sharply. High humidity (over 85%) can cause electrical components like control panels to short-circuit—install air conditioners or dehumidifiers in humid regions (e.g., southern China’s rainy season) to protect sensitive parts.

Fourth, timely lubrication and standardized operation: Lubricate moving parts (e.g., air compressor bearings, valve stems) every 3 months using manufacturer-recommended lubricating oil—follow the manual’s dosage (too much causes oil leakage, too little leads to dry friction). Train operators to stick to start/stop procedures: for example, never shut down the generator abruptly during peak operation, as this creates pressure shocks that damage valves. Together, these steps can stably boost the generator’s lifespan by ~20%.

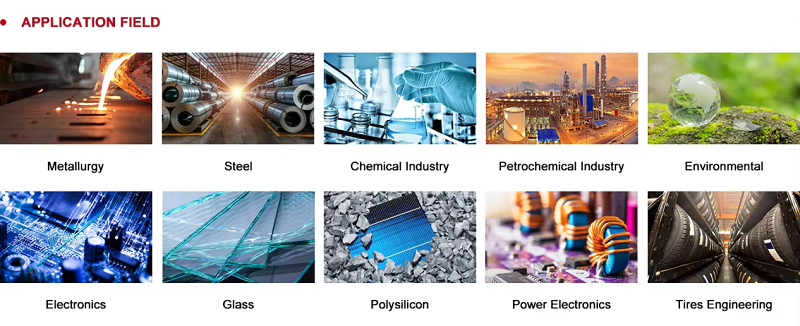

Nitrogen generators serve diverse high-demand sectors: food (modified atmosphere packaging for snacks and fresh meat, doubling shelf life), electronics (99.999% high-purity nitrogen for chip welding, preventing pin oxidation), chemicals (inert protection for flammable reactions like polyurethane synthesis, avoiding fire risks), pharmaceuticals (drug drying and vial sealing, ensuring no moisture affects drug stability), metallurgy (nitrogen-filled heat treatment for steel, preventing surface oxidation), automotive (tire inflation, reducing air leakage by 30%), and even wine making (topping up wine barrels with nitrogen, preserving flavor by displacing oxygen).

PSA nitrogen generators outperform traditional cryogenic air separation systems for most SMEs, with clear advantages: They have a smaller footprint (2-5㎡ for a 50Nm³/h unit vs. tens/hundreds of ㎡ for cryogenic systems, fitting in small workshops), 30%-50% lower initial investment (no need for large-scale cooling infrastructure), faster startup (30 mins to reach rated purity vs. 24-48 hrs of pre-cooling for cryogenic systems, ideal for batch production), flexible output (adjust nitrogen supply based on real-time demand, saving 15%-20% energy vs. cryogenic systems’ full-load only operation), and easier maintenance (ordinary staff can replace filters/desiccants, while cryogenic systems need specialized technicians for refrigerator and distillation tower upkeep).

With 20 years of deep experience in the nitrogen generator industry, we’re a leading industry-trade integrated enterprise, blending R&D, production, and global sales. For product quality, we source top-tier materials: molecular sieves from global brands (ensuring stable adsorption for 3-5 years), and electrical components from Siemens and Schneider (reducing failure rates by 80% vs. generic parts). Every generator undergoes 100% strict testing: 72-hour continuous operation (simulating real production conditions) and 5 rounds of purity checks before delivery. Our after-sales support is equally robust: a team of 30+ certified engineers offers 24/7 online consultation; for on-site issues, we guarantee arrival within 48 hours in the same province and 72 hours across provinces.

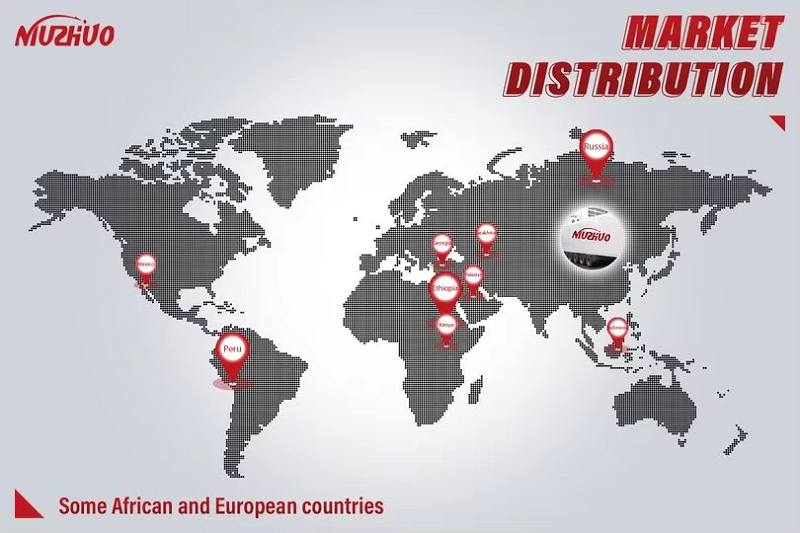

Having served 2,000+ enterprises across 12 industries (from Fortune 500 electronics firms to local food factories), we’ve built a reputation for reliability. We warmly welcome partners worldwide for technical exchanges, customized solution discussions, and business cooperation—working together to unlock the value of nitrogen technology and achieve mutual growth.

If you want to know more information, please contact us freely:

Contact:Miranda Wei

Email:miranda.wei@hzazbel.com

Mob/What’s App/We Chat:+86-13282810265

WhatsApp:+86 157 8166 4197

Post time: Aug-29-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com