With the continuous growth of oxygen demand in the global medical health and industrial fields, pressure swing adsorption (PSA) oxygen generator has become the mainstream choice in the market with its high efficiency and energy saving. This article will introduce the basic configuration, working principle and core application scenarios of PSA oxygen generator in detail.

Working principle of PSA oxygen generator

According to the principle of pressure swing adsorption, zeolite molecular sieve is used as adsorbent. Due to the selective adsorption characteristics of zeolite molecular sieve, nitrogen is adsorbed by the molecular sieve in large quantities, and oxygen is enriched in the gas phase. Nitrogen and oxygen are separated under the action of pressure swing adsorption. A double-tower or multi-tower structure is adopted, while oxygen is adsorbed and regenerated. The opening and closing of pneumatic valves are controlled by intelligent programs such as PLC, so that two or more towers are cycled alternately to continuously produce high-quality oxygen.

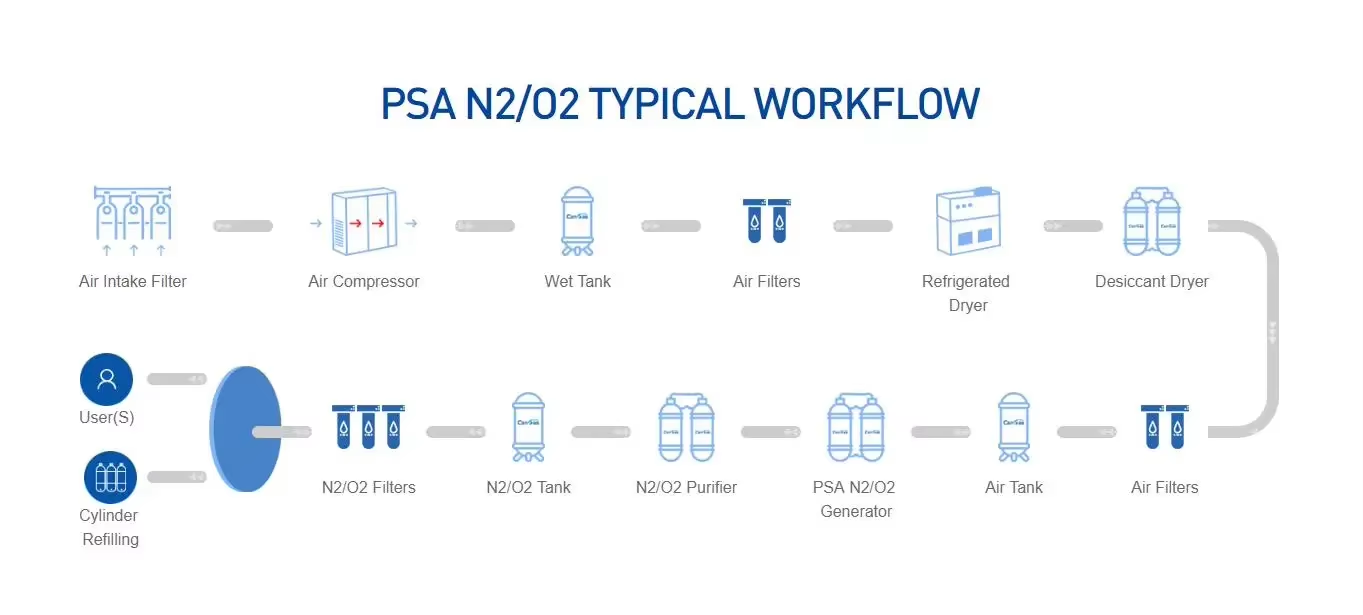

Basic configuration of PSA oxygen generator

Core components

- Air compressor: Provides raw air, which must meet the requirements of oil-free and clean to avoid contaminating the molecular sieve.

- Air storage tank: stabilizes air flow pressure and reduces compressor load fluctuations.

- Filtration system: includes primary and high efficiency filters to remove dust, moisture and oil from the air.

- Adsorption tower: built-in zeolite molecular sieve (such as 13X type) to separate nitrogen and oxygen through pressure swing adsorption.

- Control system: PLC or microcomputer automatically adjusts pressure, flow and purity, and supports real-time monitoring.

- Oxygen buffer tank: stores finished oxygen to ensure stable output. 2. Optional additional modules

- Oxygen flowmeter: accurately adjusts output (usually 1-100Nm³/h).

- Purity monitor: ensures oxygen purity of 90%-95% (medical grade requires ≥93%).

- Silencer: reduces operating noise to below 60 decibels.

Technical features

-Pressure swing adsorption is used as the process principle, mature and reliable

-Intelligent soft cycle switching, purity, and flow rate are adjustable within a certain range

-Relevant system components are reasonably configured with low failure rate

-Reasonable internal components, uniform airflow distribution, and reduced airflow impact

-Perfect process design, optimal use effect

-Unique molecular sieve protection measures to extend the service life of zeolite molecular sieve/carbon molecular sieve

-Only unqualified oxygen/nitrogen exhaust devices can be interlocked to package product oxygen/nitrogen quality

-Optional oxygen/nitrogen device flow, purity automatic adjustment system, remote control system, etc.

-Complete machine shipped, no basic device indoors

-Easy to install with pipeline pairing

-Easy to operate and stable operation, high degree of automation, and can realize unmanned operation

Application scenarios

1. Medical field: hospitals, nursing homes and home oxygen therapy, in accordance with YY/T 0298 standard.

2. Industrial field: metallurgy, chemical industry, sewage treatment and other oxygen-enriched combustion or oxidation processes.

3. Emergency support: portable oxygen supply solutions for plateau areas and disaster relief.

For any oxygen/nitrogen/argon needs, please reach out to us :

Emma Lv

Tel./Whatsapp/Wechat:+86-15268513609

Email:Emma.Lv@fankeintra.com

Facebook: https://www.facebook.com/profile.php?id=61575351504274

Post time: Jun-03-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com