Distillation tower cold box system

1. Using advanced calculation software, based on the user's climate conditions and public engineering conditions, combined with the actual experience of hundreds of air separation designs and operations, the process flow calculations and distillation tower calculations of the air separation equipment are carried out, with safety and reliability as the design basis:

1) A main cooling grounding system is set up to prevent the generation of static electricity;

2) A unique main cooling explosion-proof structure is set up to prevent nitrogen and hydrogen compounds from accumulating on the fins;

3) Strict operating and use specifications, and strict detection of the main cooling liquid level and CnHm is set up.

4) Reasonably select the flow rate of various gases, especially the flow rate of pressurized oxygen and liquid oxygen, to ensure safety; 2. The distillation tower adopts a regular packing tower, which has the characteristics of large operating flexibility, high efficiency, low resistance, and low energy consumption;

3. The main heat exchanger adopts a long plate, large-section vacuum brazed aluminum plate-fin heat exchanger, which reduces the temperature difference in the hot section, controls the loss of cold, and reduces energy consumption;

4. The pipeline in the tower has been stress analyzed, the pipeline adopts a self-compensation form, the tower body and pipeline are made of aluminum alloy, and the tower body, pipeline and valve are welded by argon arc welding; 100% non-destructive testing, in line with national standards.

Turbine expander (oil bearing & gas bearing)

1. Use advanced design and processing software to design and process performance and flow channels, so that the efficiency reaches the optimal design value, and the aerodynamic performance and flow field distribution are more reasonable;

2. While ensuring the high efficiency of the expander and the high efficiency of the booster, ensure the matching between the two and the adaptability to variable working conditions;

3. The impeller adopts a three-dimensional flow design and is processed by an advanced CNC milling machine to ensure the processing accuracy of the impeller;

4. Use an adjustable nozzle to adjust the cooling capacity.

Gas Bearing Expander

Oil Bearing Expander

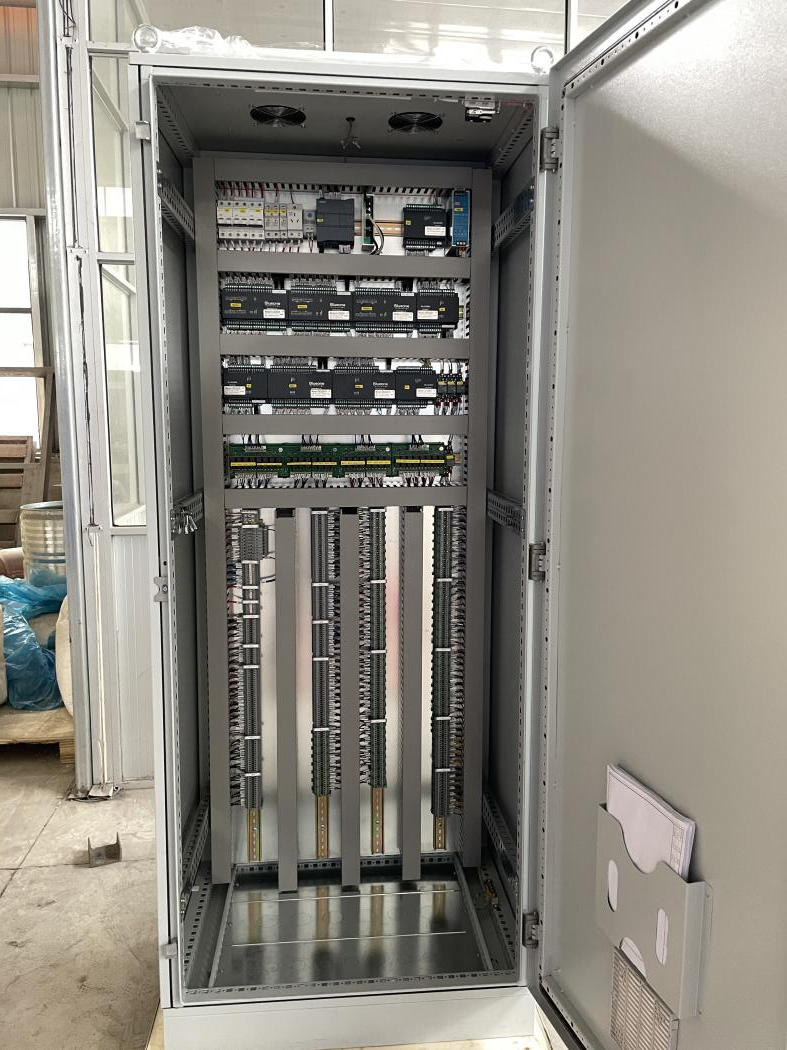

Instrument and electrical control system

1. Use a control method that combines the central control room and the machine side cabinet to effectively monitor the complete set of air separation equipment;

2. Use DCS (PLC) instrument control system to complete the display, alarm and control of the main process parameters;

3. Design and manufacture safely and reliably in accordance with Chinese national and industry standards and specifications;

4. Set up a machine side cabinet next to each unit to achieve on-site operation.

For any oxygen/nitrogen/argon needs, please reach out to us :

Emma Lv Tel./Whatsapp/Wechat:+86-15268513609

Email:Emma.Lv@fankeintra.com

Post time: Apr-29-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com