A PSA (Pressure Swing Adsorption) oxygen generator system comprises several key components, each playing a vital role in producing high-purity oxygen. Here’s a breakdown of their functions and precautions:

1. Air Compressor

Function: Compresses ambient air to provide the pressure needed for the PSA process.

Precautions: Regularly check oil levels and cooling systems to prevent overheating. Ensure proper ventilation to avoid performance degradation.

2. Refrigeration Dryer

Function: Removes moisture from compressed air to prevent corrosion in downstream components.

Precautions: Monitor dew point temperature and clean air filters periodically to maintain drying efficiency.

3. Filters

Function: Remove particulate matter, oil, and impurities from the air to protect adsorption towers.

Precautions: Replace filter elements according to the manufacturer’s schedule to avoid pressure drop.

4. Air Storage Tank

Function: Stabilizes compressed air pressure and reduces fluctuations in the system.

Precautions: Drain condensate regularly to prevent water accumulation, which may affect air quality.

5. PSA Adsorption Towers (A & B)

Function: Use zeolite molecular sieves to adsorb nitrogen from compressed air, releasing oxygen. Towers operate alternately (one adsorbs while the other regenerates).

Precautions: Avoid sudden pressure changes to prevent damage to the sieves. Monitor adsorption efficiency to ensure oxygen purity.

6. Purification Tank

Function: Further purifies oxygen by removing trace impurities, enhancing purity.

Precautions: Replace purification media as needed to maintain optimal performance.

7. Buffer Tank

Function: Stores purified oxygen, stabilizing output pressure and flow.

Precautions: Check pressure gauges regularly and ensure tight seals to prevent leaks.

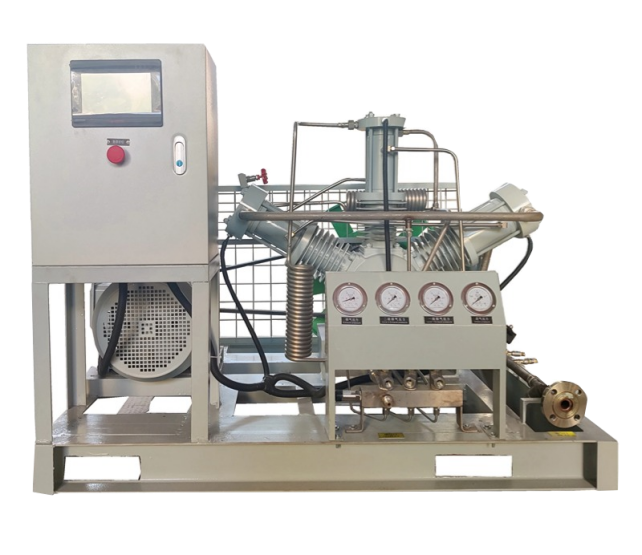

8. Booster Compressor

Function: Increases oxygen pressure for applications requiring high-pressure delivery.

Precautions: Monitor temperature and pressure limits to avoid mechanical failure.

9. Gas Filling Panel

Function: Distributes oxygen to storage cylinders or pipelines in an organized manner.

Precautions: Ensure leak-proof connections and follow safety protocols during filling.

Industries Using PSA Oxygen Generators

Medical: Hospitals for oxygen therapy and emergency care.

Manufacturing: Metal welding, cutting, and chemical oxidation processes.

Food & Beverage: Packaging to extend shelf life by replacing air with oxygen.

Aerospace: Oxygen supply for aircraft and ground support.

PSA oxygen generators offer energy-efficient, on-demand oxygen production, ideal for industries prioritizing reliability and cost-effectiveness.

We welcome collaborations to tailor PSA solutions for your specific needs. Contact us to explore how our technology can enhance your operations!

If you want to know more information, please contact us freely:

Contact:Miranda

Email:miranda.wei@hzazbel.com

Mob/What's App/We Chat:+86-13282810265

WhatsApp:+86 157 8166 4197

Post time: Jun-13-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com