In the modern industrial production system, industrial oxygen generators are key equipment, widely used in many fields such as metallurgy, chemical industry, and medical treatment, providing an indispensable oxygen source for various production processes. However, any equipment may fail during long-term operation. Understanding common failures and solutions is extremely important to ensure production continuity.

Power supply and startup failure

1. Phenomenon: The machine does not run and the power indicator light is off

Reason: The power is not connected, the fuse is blown, or the power cord is broken.

Solution:

Check whether the socket has electricity and replace the damaged fuse or power cord.

Confirm that the power supply voltage is stable (such as 380V system needs to be kept within ±10%).

2. Phenomenon: The power indicator light is on but the machine does not run

Reason: The compressor overheat protection starts, the starting capacitor is damaged, or the compressor fails.

Solution:

Stop and cool for 30 minutes before restarting to avoid continuous operation for more than 12 hours;

Use a multimeter to detect the starting capacitor and replace it if it is damaged;

If the compressor is damaged, it needs to be returned to the factory for repair.

Abnormal oxygen output

1. Phenomenon: Complete lack of oxygen or low flow

Reason:

Filter is clogged (secondary air intake/humidification cup filter);

Air pipe is detached or pressure regulating valve is improperly adjusted.

Solution:

Clean or replace the clogged filter and filter element;

Reconnect the air pipe and adjust the pressure regulating valve to 0.04MPa pressure.

2. Phenomenon: The flow meter float fluctuates greatly or does not respond

Reason: The flow meter is closed, the pipeline is leaking or the solenoid valve is faulty.

Solution:

Turn the flow meter knob counterclockwise to check if it is stuck;

Check the pipeline sealing, repair the leaking point or replace the damaged solenoid valve.

Insufficient oxygen concentration

1. Phenomenon: Oxygen concentration is lower than 90%

Reason:

Molecular sieve failure or powder blocking pipeline;

System leakage or compressor power reduction.

Solution:

Replace adsorption tower or clean exhaust pipe;

Use soapy water to detect pipeline sealing and repair leaks;

Check whether the compressor output pressure meets the standard (usually ≥0.8MPa).

Mechanical and noise problems

1. Phenomenon: Abnormal noise or vibration

Reason:

Safety valve pressure is abnormal (exceeding 0.25MPa);

Improper installation of compressor shock absorber or pipeline kink.

Solution:

Adjust the safety valve starting pressure to 0.25MPa;

Reinstall the shock absorber spring and straighten the intake pipeline.

2. Phenomenon: Equipment temperature is too high

Reason: Heat dissipation system failure (fan shutdown or circuit board damage)[citation:9].

Solution:

Check whether the fan power plug is loose;

Replace the damaged fan or heat dissipation control module.

V. Humidification system failure

1. Phenomenon: No bubbles in the humidification bottle

Reason: The bottle cap is not tightened, the filter element is blocked by scale or leaking.

Solution:

Reseal the bottle cap and soak the filter element with vinegar water to clean it;

Block the oxygen outlet to test whether the safety valve is opened normally.

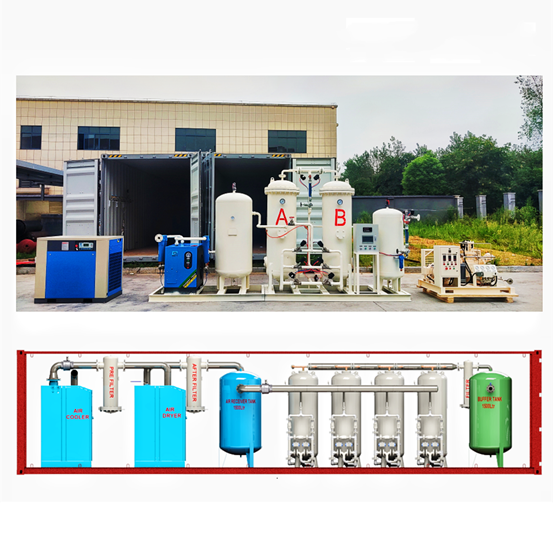

NUZHUO GROUP has been committed to the application research, equipment manufacturing and comprehensive services of normal temperature air separation gas products, providing high-tech enterprises and global gas product users with suitable and comprehensive gas solutions to ensure customers achieve excellent productivity. For more information or needs, please feel free to contact us: 18624598141/zoeygao@hzazbel.com.

Post time: May-24-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com