Argon (symbol Ar, atomic number 18) is a noble gas distinguished by its inert, colorless, odorless, and tasteless characteristics—traits that make it safe for closed or confined environments. Comprising approximately 0.93% of Earth’s atmosphere, it is far more abundant than other noble gases like neon (0.0018%) or krypton (0.00011%), giving it a natural advantage for large-scale use. Its chemical stability stems from a full outer electron shell (eight valence electrons), which means it almost never forms compounds with other elements—even at high temperatures or under extreme pressure. At standard temperature and pressure (STP), argon exists as a monatomic gas (composed of single atoms, unlike diatomic oxygen or nitrogen), with a boiling point of -185.8°C and a freezing point of -189.3°C. These ultra-low temperatures mean it requires cryogenic storage, but they also make it ideal for applications like cooling sensitive equipment, as it doesn’t react with materials even when chilled to near-absolute zero.

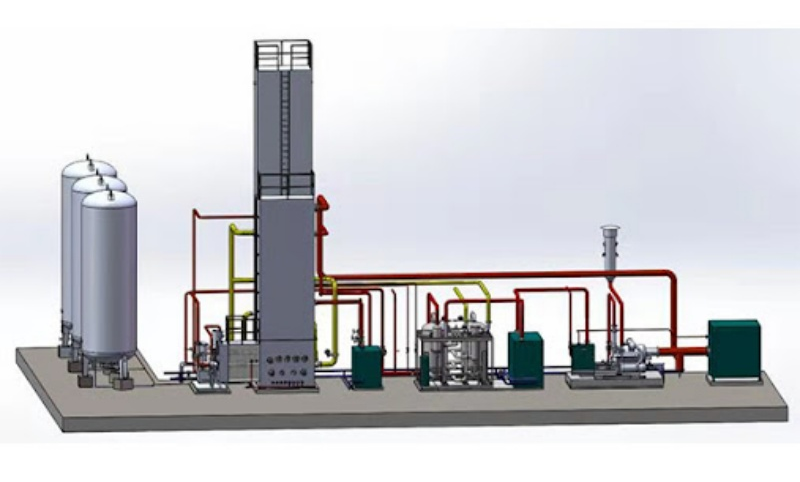

Argon is most commonly separated from air through fractional distillation, a precise, multi-step process. First, atmospheric air is filtered to remove dust, water vapor, and carbon dioxide—impurities that could disrupt cooling or contaminate the final product. Next, the purified air is compressed and cooled in a heat exchanger, eventually reaching -200°C, which converts it into a liquid. This liquid air is then pumped into a tall distillation tower, where it is heated slowly. Because different gases in air have unique boiling points—nitrogen boils at -195.8°C (lower than argon), oxygen at -183°C (higher than argon)—they vaporize at different levels of the tower. Nitrogen gas rises to the top and is collected first, while oxygen remains liquid at the bottom. Argon, with its intermediate boiling point, condenses in the middle of the tower, where it is siphoned off. The collected argon is then sent through a second purification step to remove any remaining nitrogen or oxygen, resulting in industrial-grade argon (99.99% pure) or ultra-pure argon (99.999% pure) for high-tech uses.

Argon’s inertness makes it indispensable across multiple industries. In metallurgy, it is a critical shielding gas for welding processes like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. When used to weld metals such as aluminum, stainless steel, or titanium, it creates a protective barrier around the weld zone, preventing oxidation that would weaken the joint or cause defects—essential for manufacturing car frames, airplane parts, and construction materials. The electronics industry relies on ultra-pure argon to manufacture semiconductors: during the deposition of thin metal or silicon layers on microchips, argon fills the production chamber, ensuring no air particles contaminate the delicate circuits. Beyond heavy industry, argon extends the lifespan of incandescent light bulbs by slowing the evaporation of tungsten filaments (doubling bulb life compared to air-filled bulbs) and preserves historical artifacts—like ancient manuscripts or fragile textiles—in museum display cases, where it replaces oxygen to stop decay. It also plays a role in food packaging, where it is mixed with nitrogen to flush out oxygen, keeping baked goods, snacks, and fresh produce fresh for longer.

Economically, argon is a high-value resource due to its widespread demand and low production costs. Since its raw material is air—an infinite, free resource—fractional distillation is cost-effective, especially when paired with nitrogen or oxygen production (many plants produce all three gases simultaneously, reducing overhead). The global argon market is valued at over $8 billion annually, with steady growth of 5–7% per year. This growth is driven by industries like automotive (as electric vehicle production increases, requiring more precision welding), electronics (expanding 5G and semiconductor manufacturing), and renewable energy (solar panel production uses argon to coat photovoltaic cells). Unlike rarer noble gases (krypton costs 10–20 times more, xenon 50–100 times more), argon’s affordability makes it accessible for both large factories and small laboratories. As global technology and infrastructure development accelerates, demand for argon is expected to rise further, solidifying its role as a key enabler of industrial growth and technological innovation worldwide.

If you want to know more information, please contact us freely:

Contact:Miranda Wei

Email:miranda.wei@hzazbel.com

Mob/What’s App/We Chat:+86-13282810265

WhatsApp:+86 157 8166 4197

插入的链接:https://www.hznuzhuo.com/cryogenic-oxygen-plant/

Post time: Sep-05-2025

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com