Ukuhlukaniswa komoya okujulile kwe-cryogenic kuyinqubo ehlukanisa umoya-mpilo, i-nitrogen namanye amagesi emoyeni kusetshenziswa ubuchwepheshe obusezingeni eliphansi lokushisa. Njengendlela ethuthukisiwe yokukhiqiza igesi yezimboni, ukuhlukaniswa komoya okujulile kwe-cryogenic kusetshenziswa kabanzi ezimbonini ezifana ne-metallurgy, ubunjiniyela bamakhemikhali kanye ne-electronics. Ukwakhiwa kwemishini yokuhlukanisa umoya ejulile ye-cryogenic akudingi nje kuphela ukunemba kwezobuchwepheshe kodwa futhi nokuhambisana nezindinganiso zezimboni kanye nezidingo zamakhasimende ukuze kuqinisekiswe ukusebenza okuzinzile kanye nezinzuzo zezomnotho. Lesi sihloko sizoxoxa ngezidingo zokuklama zemishini yokuhlukanisa umoya ejulile ye-cryogenic, ehlanganisa ukucatshangelwa komklamo oyinhloko, amaphuzu wobunjiniyela, kanye nezinyathelo zokuphepha ekusebenziseni okungokoqobo.

1. Dizayina izidingo eziyisisekelo

Lapho uklama umshini ophelele wokuhlukanisa umoya we-cryogenic ojulile, izidingo zokuqala eziyisisekelo okufanele zinqunywe zihlanganisa umthamo wokukhiqiza, izimo zomoya oluhlaza, ukuhlanzeka komkhiqizo kanye nenani, njll. Kuye ngezinkambu ezihlukene zokufaka isicelo, umthamo wokukhiqiza wemishini yokuhlukanisa umoya ejulile ye-cryogenic iyahlukahluka kakhulu, ngokuvamile isukela kumakhulu kuya ezinkulungwaneni zama-cubic metres ngehora. Ngaphezu kwalokho, ukungcola emoyeni oluhlaza, njengomswakama kanye ne-carbon dioxide, kudingeka kususwe ngesiteji sokwelashwa kwangaphambili ukuze kuqinisekiswe ukuthi imishini ingenza imisebenzi ejulile ye-cryogenic ngaphansi kwezimo ezinzile nezingaphazamiseki. Ngakho-ke, ukuklanywa kwesistimu yokwelashwa kwangaphambili kudinga ukucabangela ngokugcwele amazinga okungcola komoya wendawo kanye nendawo yokusebenza yemishini.

2. Ukucatshangelwa kwesakhiwo sesistimu

Inqubo yokuklama yemishini yokuhlukanisa umoya ye-cryogenic ejulile ihilela izinhlelo eziningi ezibalulekile, okuhlanganisa uhlelo lokucindezela, uhlelo lokushintshanisa ukushisa, uhlelo lokuhlukanisa umbhoshongo kanye nesistimu yokuphuza utshwala. Ukuklanywa kwesistimu yokucindezela kudinga ukuqinisekisa ukuhlinzekwa okusebenzayo nokuthembekile komoya ophezulu wengcindezi ofanele ukuhlukaniswa okujulile kwe-cryogenic. Izishintshi zokushisa ziyizingxenye eziyinhloko eziqinisekisa ukugcwaliseka kwenqubo ejulile ye-cryogenic, edinga ukusebenza kahle kokushisa okuphezulu. Ngokuvamile, izishintshi zokushisa ze-plate-fin zisetshenziselwa ukuqinisekisa ukudluliswa kokushisa okuphumelelayo nokugeleza kwegesi okufanayo. Ngasikhathi sinye, ukuklanywa kombhoshongo wokuhlukanisa kanye nesistimu yokugcoba i-distillation idinga ukuhlangabezana nezidingo zokuhlanzeka kwegesi yomkhiqizo, ngakho-ke ukukhethwa kokupakisha, amathreyi kanye nokwenza kahle kwezimo zenqubo ye-distillation nakho kubaluleke kakhulu. Embhoshongweni we-distillation, izingxenye ezihlukahlukene zegesi zihlukaniswa ngokuphumelelayo ngokushintshaniswa kokushisa okuphindaphindiwe kanye nezinqubo zokuhwamuka kwe-condensation, zakha umoya-mpilo ohlanzekile, i-nitrogen noma i-argon gases.

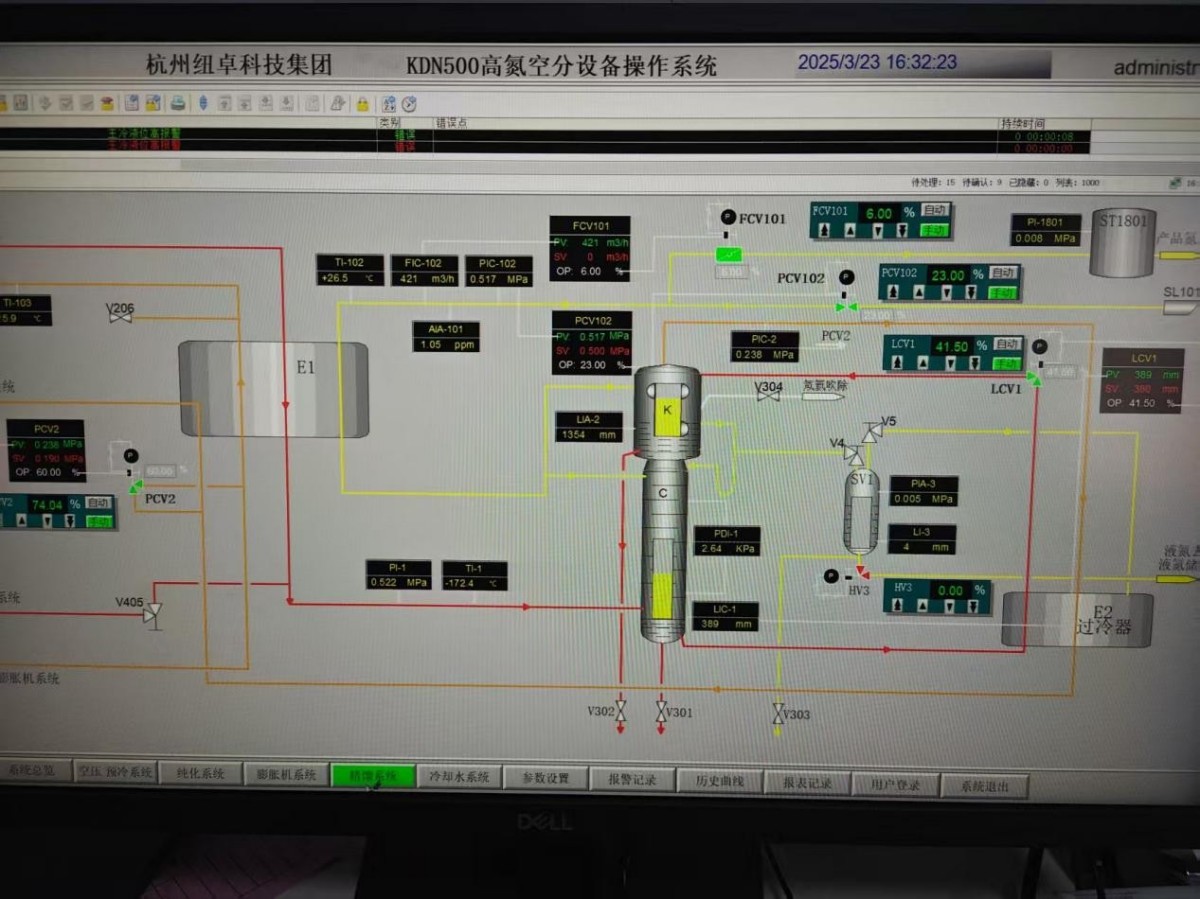

3. Amasistimu wokuzenzakalela nokulawula

Ukulawula okuzenzakalelayo kuyingxenye ebalulekile yokwakhiwa kwezinhlelo ezijulile zokuhlukanisa umoya we-cryogenic. Imishini yesimanje yokuhlukanisa umoya ejulile ye-cryogenic ngokuvamile ihlanganisa uhlelo lokulawula oluzenzakalelayo ngokugcwele ukuze kuzuzwe ukulawula okunembile kwamapharamitha afana nezinga lokushisa, ingcindezi nokugeleza. Lokhu akunciphisi kakhulu kuphela ubunzima bokusebenza kodwa futhi kuthuthukisa ukuphepha nokuzinza kohlelo. Isistimu yokulawula inqubo ngokuvamile iqukethe i-PLC (I-Programmable Logic Controller) kanye ne-DCS (Isistimu Yokulawula Okusabalalisa), eqoqa amapharamitha angukhiye ngesikhathi sangempela sokulawula nokwenza kahle, okuqinisekisa ukusebenza okuzinzile kwezisetshenziswa ngaphansi kwezimo ezihlukahlukene zomthwalo. Ukuze ubhekane nezimo eziphuthumayo, uhlelo lokulawula ludinga nokuba namandla okuxilongwa kwamaphutha, olukwazi ukubona ngokushesha izinkinga ezingaba khona futhi luthathe izinyathelo ezihambisanayo.

4. Ukucatshangelwa ukonga amandla kanye nokuvikelwa kwemvelo

Ukonga amandla kuwukucatshangelwa okubalulekile ekwakhiweni kwemishini yokuhlukanisa umoya ejulile ye-cryogenic. Idizayini esebenzayo yama-compressor kanye nezishintshisi zokushisa zidlala indima ebalulekile ekwehliseni ukusetshenziswa kwamandla. Ukwengeza, ukubuyiswa kokushisa okulahlwayo kuyindlela evamile yokonga amandla, engasebenzisa ukushisa okulahlwayo okuvela enqubweni yesiqandisi ukuze kunikeze ukwesekwa kwamandla kwezinye izinqubo, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kwawo wonke amandla. Mayelana nokuvikelwa kwemvelo, umklamo ojulile wokuhlukanisa umoya we-cryogenic udinga ukucabangela ngokugcwele izinkinga ezingase zibe khona zokungcoliswa kwemvelo enqubweni yokukhiqiza, njengokungcoliswa komsindo nokukhishwa kwegesi ekhishwayo. Ngesikhathi sokuklama, ukwelashwa kwe-insulation yomsindo kanye nezinhlelo ezifanele zokwelashwa kwegesi ekhishwayo kufanele kwengezwe ukuze kuhlangatshezwane nemithetho nezindinganiso ezifanele zokuvikela imvelo.

5. Ukusebenza kahle kwezindleko nokukhethwa kwemishini

Ukuhlolwa kokusebenza kahle kwezindleko zemishini yokuhlukanisa umoya ejulile ye-cryogenic kuthinta ngokuqondile ukuklama nokukhethwa kwayo. Ngaphansi kwesisekelo sokuhlangabezana nezidingo zokukhiqiza, ukukhethwa nesikali samathuluzi kumele sibe phansi ngokusemandleni ngokwezindleko zokuqala zokutshala kanye nezindleko zokusebenza. Ukukhethwa kwezinto zokukhiqiza, ukusebenza kahle kokushintshana kokushisa, izinhlobo zama-compressor kanye nokukhetha kokugeleza kwenqubo yizo zonke izici ezibalulekile ezithinta ukusebenza kahle kwezindleko. Ukukhethwa kwemishini efanele akunciphisi nje kuphela ukutshalwa kwezimali kokuqala kodwa futhi kwehlisa ngempumelelo izindleko zokunakekela kanye nokusebenza ngokuhamba kwesikhathi, ngaleyo ndlela kuzuze izinzuzo eziphezulu zezomnotho phakathi nenqubo yokukhiqiza.

6. Ukufakwa Esizeni Nokugunyazwa

Ukuklanywa kwemishini yokuhlukanisa umoya ye-cryogenic ephelele ejulile ayikhawulelwe esiteji sokudweba; Kudingeka futhi ukuthi icabangele izidingo zokufakwa kanye nokusebenza esizeni. Ngesikhathi sokufakwa, ukuqondanisa okunembayo kwengxenye ngayinye kufanele kuqinisekiswe ukuze kugwenywe ukuvuza ekuxhumekeni kwamapayipi. Ngesikhathi senqubo yokugunyazwa, ukuhlolwa okuphelele kwesimo sokusebenza kwesistimu ngayinye kuyadingeka ukuze kuqinisekiswe ukuthi okokusebenza kusebenza ngendlela efanele. Ngenxa yobunkimbinkimbi bemishini yokuhlukanisa umoya ye-cryogenic ejulile, ukugunyazwa kuvame ukwenziwa ithimba lonjiniyela abaqeqeshiwe, okuhlanganisa ukuhlolwa okuningi nokulungiswa kwemingcele efana nokuhlanzeka kwegesi, ingcindezi, kanye nesilinganiso sokugeleza, ekugcineni ukuhlangabezana nezidingo zokuklama kanye namazinga amakhasimende.

Ngezinguquko eziqhubekayo ezidingweni zezimboni kanye nentuthuko yezobuchwepheshe, idizayini yemishini yokuhlukanisa umoya ejulile ye-cryogenic nayo ithuthukiswa njalo. Imishini yokuhlukanisa umoya ye-cryogenic yesikhathi esizayo izogcizelela kakhulu ubuhlakani kanye nohlaza. Ngokwethula ubuchwepheshe bokuzwela obuthuthukisiwe kanye nobuchwepheshe be-inthanethi Yezinto (IoT), okokusebenza kungafinyelela ukuqapha nokuphatha okukude, futhi kungathuthukisa ukusetshenziswa kwamandla ngempumelelo kakhulu. Ngaphezu kwalokho, ukusetshenziswa kwezinto ezintsha, njengezinto ezisebenza kahle zokushintsha ukushisa nezinto zesakhiwo ezimelana nezinga lokushisa eliphansi, kuzothuthukisa kakhulu ukusebenza nempilo yemishini. Esimweni soguquko oluqhubekayo lwesakhiwo samandla, imishini yokuhlukanisa umoya ejulile ye-cryogenic izophinde isetshenziswe kabanzi ekukhiqizeni amandla ahlanzekile njenge-hydrogen, okunomthelela ekuzuzeni umgomo wokungathathi hlangothi kwe-carbon.

Ukuze uthole noma yiziphi izidingo ze-oxygen/nitrogen, sicela usithinte:

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Isikhathi sokuthumela: Jun-23-2025