Deep cryogenic air separation inzira inoparadzanisa okisijeni, nitrogen uye mamwe magasi kubva kumhepo uchishandisa tekinoroji yakaderera. Senzira yepamberi yekugadzira gasi yemaindasitiri, yakadzika cryogenic kupatsanurwa kwemhepo inoshandiswa zvakanyanya mumaindasitiri akadai sesimbi, makemikari engineering, uye zvemagetsi. Iyo dhizaini yakakwana yakadzika cryogenic mhepo yekuparadzanisa michina inoda kwete chete kurongeka kwehunyanzvi asiwo kutevedzera zviyero zveindasitiri uye zvinodiwa nevatengi kuti ive nechokwadi chekushanda kwakagadzikana uye mabhenefiti ehupfumi. Ichi chinyorwa chichakurukura zvinodiwa zvekugadzira zveyakadzika yakadzika cryogenic mhepo yekuparadzanisa michina, inovhara musimboti dhizaini kufunga, mainjiniya mapoinzi, uye yekudzivirira mukushandisa zvinoshanda.

1. Gadzira zvakakosha zvinodiwa

Paunenge uchigadzira yakakwana yakadzika cryogenic mhepo yekuparadzanisa midziyo, yekutanga yekutanga zvinodiwa kuti zvitemerwe zvinosanganisira kugadzirwa kwesimba, mbishi mamiriro emhepo, kuchena kwechigadzirwa uye huwandu, etc. Zvichienderana neakasiyana minda yekushandisa, kugona kwekugadzira kweyakadzama cryogenic mhepo yekuparadzanisa michina inosiyana zvakanyanya, kazhinji kubva kumazana kusvika kuzviuru zvecubic metres paawa. Mukuwedzera, kusvibiswa mumhepo yakasvibirira, yakadai sehunyoro uye carbon dioxide, inoda kubviswa kuburikidza ne-pre-atreatment stage kuti ive nechokwadi chokuti michina inogona kuita zvakadzika cryogenic maitiro pasi pemamiriro akagadzikana uye asina kukanganisa. Nokudaro, kugadzirwa kwegadziriro yepamberi yekurapa inoda kunyatsofungisisa mazinga ekusvibisa emhepo yemunharaunda uye nzvimbo yekushanda yemidziyo.

2. Maonero ekugadzirisa maitiro

Maitiro ekugadzira yakadzika cryogenic mhepo yekuparadzanisa michina inosanganisira akawanda makiyi masisitimu, anosanganisira compression system, heat exchange system, separation tower system uye distillation system. Iyo dhizaini yekumanikidza system inoda kuve nechokwadi chekuita uye yakavimbika kupihwa kwepamusoro-kudzvanywa mweya wakakodzera kwakadzika cryogenic kupatsanurwa. Heat exchangers ndiyo yakakosha zvikamu zvinovimbisa kuzadzikiswa kweiyo yakadzika cryogenic process, inoda yakanyanya kupisa kunyatsoshanda. Kazhinji, plate-fin heat exchangers inoshandiswa kuve nechokwadi chekufambisa kupisa kwakanaka uye yunifomu gasi kuyerera. Panguva imwecheteyo, dhizaini yeshongwe yekuparadzanisa uye distillation system inoda kuzadzisa kuchena zvinodiwa zvegasi rechigadzirwa, saka kusarudzwa kwekurongedza, matireyi uye optimization yemamiriro ekuita distillation akakosha zvakare. Mune distillation tower, zvikamu zvakasiyana-siyana zvegasi zvinonyatsoparadzaniswa kuburikidza nekudzokororwa kwekupisa kupisa uye condensation evaporation maitiro, kuumba yakakwirira-kuchena okisijeni, nitrogen kana argon magasi.

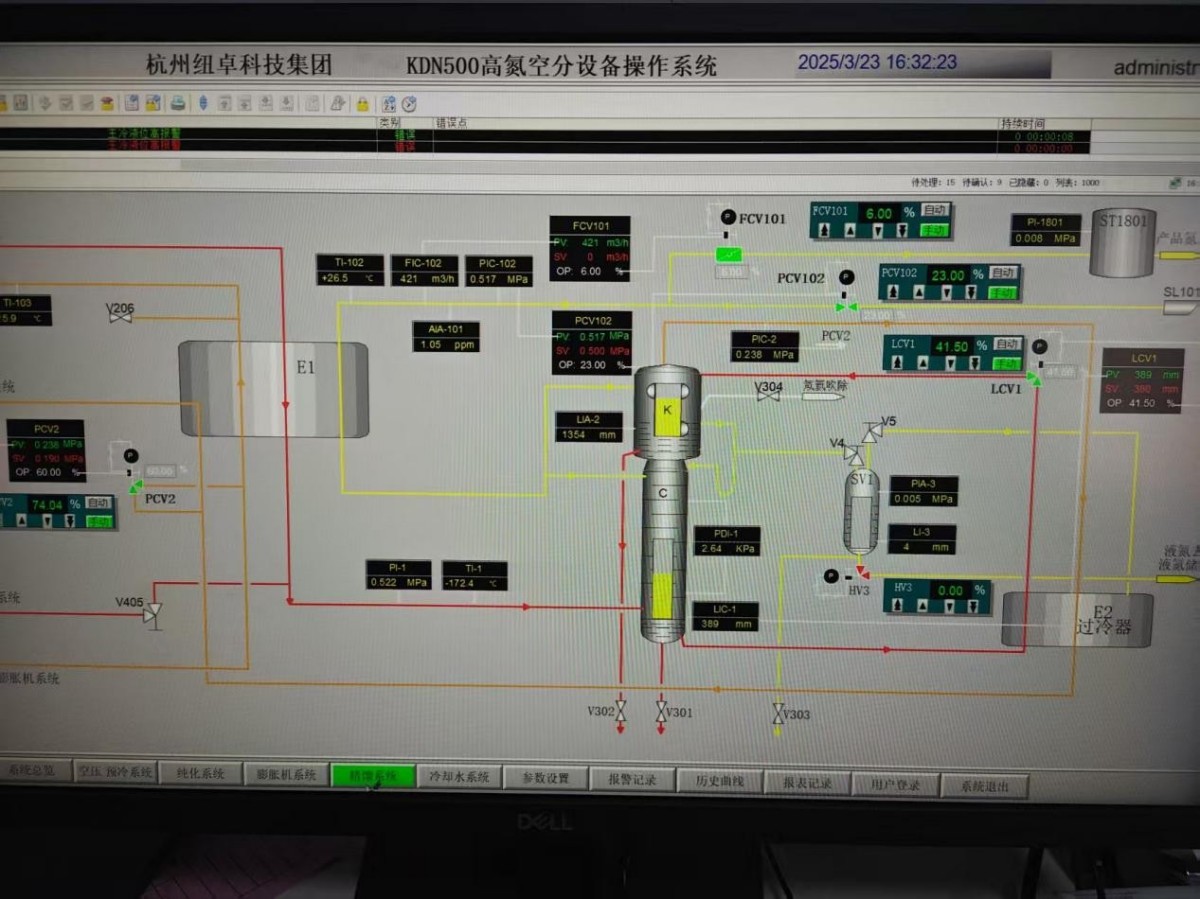

3. Automation uye control systems

Automation control chikamu chakakosha chedhizaini yakadzika cryogenic mhepo yekuparadzanisa masisitimu. Yemazuva ano yakakwana yakadzika cryogenic mhepo yekuparadzanisa michina inowanzo batanidza yakazara otomatiki yekudzora sisitimu kuti iwane chaiyo kutonga kwema parameter senge tembiricha, kudzvanywa uye kuyerera. Izvi hazvisi kungoderedza zvakanyanya kuoma kwekushanda asiwo kunovandudza kuchengetedzwa uye kugadzikana kwehurongwa. Iyo process control system inowanzo ine PLC (Programmable Logic Controller) uye DCS (Distributed Control System), iyo inounganidza yakakosha paramita munguva chaiyo yekutonga nekugadzirisa, kuve nechokwadi chekushanda kwakagadzikana kwemidziyo pasi pemamiriro akasiyana-siyana emutoro. Kuti utarise nekukurumidzira, iyo yekudzora sisitimu inodawo kuve nekutadza kuongororwa kugona, inokwanisa kuona nekukasika matambudziko angangoitika uye kutora matanho anoenderana.

4. Kuchengetedza magetsi uye kuchengetedzwa kwezvakatipoteredza kufunga

Kuchengetedza magetsi ndiko kutariswa kwakakosha mukugadzira yakadzika cryogenic mhepo yekuparadzanisa michina. Kubudirira dhizaini yemacompressors uye kupisa kunopisa kunoita basa rakakosha mukuderedza kushandiswa kwesimba. Pamusoro pezvo, kutambisa kupisa kudzoreredza chiyero chakajairwa chekuchengetedza simba, chinogona kushandisa kupisa kwemarara kubva mufiriji maitiro kupa rutsigiro rwesimba kune mamwe maitiro, nekudaro kuvandudza iyo yakazara simba rekushandisa. Panyaya yekuchengetedzwa kwezvakatipoteredza, yakadzika cryogenic mhepo yekuparadzanisa dhizaini inoda kunyatso funga nezveangangove matambudziko ekusvibiswa kwezvakatipoteredza mukugadzira maitiro, sekusvibiswa kweruzha uye exhaust gasi. Munguva yekugadzira nhanho, ruzha rwekudzivirira kwekudzivirira uye hurongwa hwakakodzera hwekurapa gasi hunoda kuwedzerwa kusangana nemirairo yekudzivirira kwezvakatipoteredza uye zviyero zvinodiwa.

5. Kubhadhara mari uye kusarudzwa kwemidziyo

Iko mari-inoshanda yekuongorora yakakwana yakadzika cryogenic mhepo yekuparadzanisa michina inobata zvakananga dhizaini yayo uye kusarudzwa. Pasi pechikonzero chekusangana nezvinodiwa zvekugadzira, kusarudzwa uye chiyero chemidziyo inofanirwa kunge yakaderera sezvinobvira maererano nemutengo wekutanga wekudyara uye mutengo wekushandisa. Kusarudzwa kwezvinhu zvekugadzira, kupisa kwekutsinhanisa kunyatsoita, mhando dzemacompressors uye kuyerera kwemaitiro sarudzo zvese zvakakosha zvinokanganisa mutengo-kubudirira. Kusarudzwa kwakakodzera kwemidziyo hakungodzikisire mari yekutanga chete asi zvakare zvinobudirira kudzikisa kuchengetedza uye mari yekushandisa mukufamba kwenguva, nekudaro kuwana kudzoka kwehupfumi hwepamusoro panguva yekugadzira.

6. Pa-saiti Kuiswa uye Kutumwa

Iyo dhizaini yakakwana yakadzika cryogenic mhepo yekuparadzanisa michina haina kuganhurirwa padanho rekudhirowa; inodawo kufunga nezvezvinodiwa zvekuisa pa-saiti uye kutumwa. Munguva yekuisa nhanho, kurongeka chaiko kwechikamu chimwe nechimwe kunofanirwa kuve nechokwadi kuti kudzivirira kuvuza pakubatanidza pombi. Munguva yekutumwa kwekuita, kuongororwa kwakadzama kwemamiriro ekushanda kwegadziriro yega yega inodiwa kuti ive nechokwadi chekuti michina inoshanda pamamiriro ayo chaiwo. Nekuda kwekuoma kwezvakadzama cryogenic mhepo yekuparadzanisa michina, kutumwa kunowanzoitwa nenyanzvi yeinjiniya timu, kusanganisira bvunzo dzakawanda uye kugadziridzwa kweparameter senge gasi kuchena, kudzvanywa, uye kuyerera kwehuwandu, pakupedzisira kusangana nezvinodiwa zvekugadzira uye zviyero zvevatengi.

Nekuchinja kuri kuenderera mberi kwezvido zvemaindasitiri uye kufambira mberi kwetekinoroji, dhizaini yakadzika cryogenic mhepo yekuparadzanisa michina iri kugara ichigadziriswa. Ramangwana rakadzika cryogenic mhepo yekuparadzanisa michina ichaisa simbiso huru pahungwaru uye kusvibira. Nekuunza tekinoroji yekunzwa uye Internet yeZvinhu (IoT) matekinoroji, michina inogona kuwana kuremerwa kwekutarisa uye manejimendi, uye inogona kunyatso wedzera mashandisiro esimba. Pamusoro pezvo, kushandiswa kwezvinhu zvitsva, senge zvinobudirira zvinopisa zvinopisa uye zvimwe zvakaderera-zvinodzivirira kutonhora zvimiro, zvichawedzera kuwedzera kushanda uye hupenyu hwemidziyo. Mumamiriro ezvinhu ekuchinja kunoramba kuripo kwechimiro chesimba, yakadzika cryogenic mhepo yekuparadzanisa michina ichashandiswawo zvakanyanya mukugadzirwa kwesimba rakachena senge hydrogen, zvichibatsira pakuzadzikiswa kwechinangwa chekusarerekera kabhoni.

Kune chero oxygen / nitrogen inoda, ndapota svika kwatiri:

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Nguva yekutumira: Jun-23-2025